Aluminum Tool Boxes For Pickup Trucks: The Ultimate Guide to Secure and Organized Storage pickup.truckstrend.com

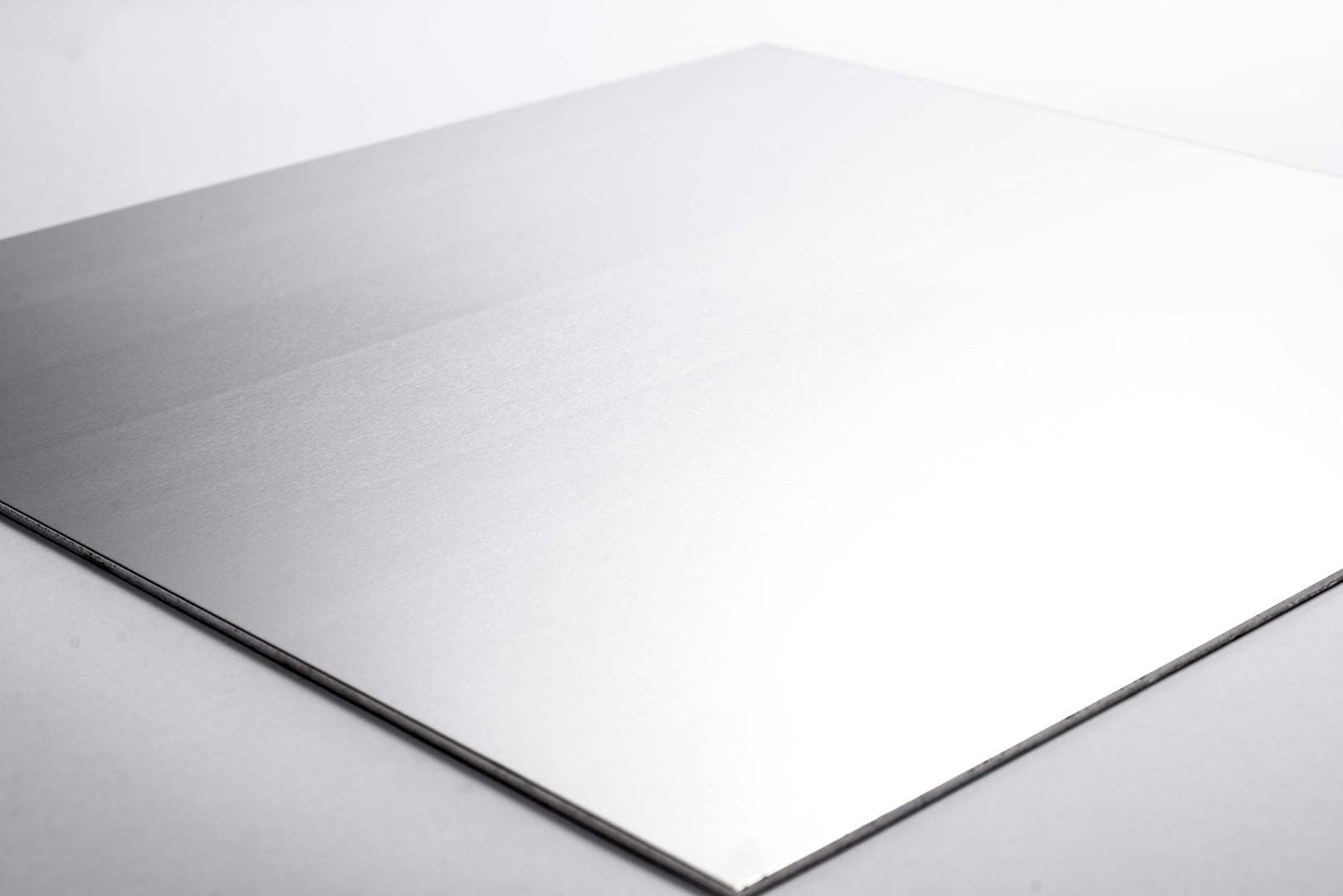

In the world of pickup trucks, utility is king. Whether you’re a seasoned contractor, a dedicated DIY enthusiast, an adventurous overlander, or simply someone who values an organized vehicle, the need for secure, weather-resistant, and easily accessible storage is paramount. Enter the aluminum tool box for pickup trucks – an indispensable accessory that transforms your truck bed into a mobile, organized workspace. More than just a simple box, these robust containers offer a lightweight yet incredibly durable solution for protecting your tools, gear, and valuables from the elements and theft, while keeping them readily available whenever duty calls.

Why Choose Aluminum for Your Pickup Truck Tool Box?

Aluminum Tool Boxes For Pickup Trucks: The Ultimate Guide to Secure and Organized Storage

When it comes to truck bed storage, various materials are available, but aluminum consistently stands out as the superior choice. Its unique properties make it ideal for the demanding environment of a pickup truck, offering a compelling blend of benefits:

- Exceptional Durability with Lightweight Design: Aluminum boasts an impressive strength-to-weight ratio. Unlike steel, which is heavy and can significantly impact fuel efficiency, aluminum provides robust protection without adding excessive bulk. This means less strain on your truck’s suspension and better gas mileage, all while offering ample resistance to dents, dings, and impacts.

- Superior Corrosion Resistance: One of aluminum’s most significant advantages is its natural resistance to rust and corrosion. Unlike steel, which requires special coatings to prevent oxidation, aluminum forms a protective oxide layer when exposed to air, effectively preventing rust. This makes it perfect for outdoor use, enduring rain, snow, road salt, and harsh chemicals without degrading.

- Enhanced Security: Aluminum tool boxes are designed with security in mind. Their rigid construction, often featuring reinforced lids and high-quality locking mechanisms (such as paddle latches or push-button locks with keys), makes them incredibly difficult for unauthorized access. This peace of mind is invaluable for protecting expensive tools and equipment.

- Sleek Appearance and Low Maintenance: Aluminum tool boxes, particularly those with a diamond plate finish or powder-coated black, offer a professional and clean aesthetic that complements any pickup truck. They are also remarkably easy to maintain, typically requiring only a simple wash with soap and water to keep them looking new.

- Thermal Conductivity: While perhaps less critical than durability or corrosion resistance, aluminum’s thermal properties mean it dissipates heat more effectively than steel. This can be a minor benefit in preventing excessive heat buildup inside the box on hot days, though it won’t keep contents perfectly cool.

Types of Aluminum Tool Boxes for Pickup Trucks

The market offers a diverse range of aluminum tool boxes, each designed to fit specific needs and truck bed configurations. Understanding the different types is crucial for making the right choice:

- Crossover/Cross-Bed Tool Boxes: This is arguably the most popular type. It spans the width of the truck bed, sitting behind the cab and resting on the bed rails. Crossover boxes are excellent for providing a large, accessible storage area without taking up too much floor space, allowing for longer items to be carried underneath. They often feature a single lid or gull-wing (two-lid) design.

- Side-Mount/Saddle Boxes: These boxes are designed to mount on top of the truck bed rails, running along the side. They are ideal for storing smaller tools and equipment, keeping them organized and easily accessible from the side of the truck. Side-mount boxes leave the majority of the truck bed open for larger cargo.

- Underbody Tool Boxes: Mounted underneath the truck’s frame, typically behind the rear wheels or beneath the cab, underbody boxes are perfect for commercial vehicles or those needing discrete storage while keeping the bed entirely clear. They are often used for chains, straps, or emergency equipment.

- Chest Tool Boxes: These are standalone boxes that sit directly on the truck bed floor. They are highly versatile, can be easily removed when the bed is needed for other cargo, and come in various sizes. Chest boxes are good for general storage but do consume bed floor space.

- Wheel Well Tool Boxes: Designed to fit snugly over the truck’s wheel wells, these boxes utilize often-wasted space. They are typically smaller but offer convenient, out-of-the-way storage for smaller items, leaving the central bed area clear.

- Fifth-Wheel Tool Boxes: Specifically designed for trucks equipped with a fifth-wheel hitch, these boxes are usually low-profile and fit in the front of the bed without interfering with the hitch mechanism. They provide secure storage without compromising towing capabilities.

Key Features to Look For When Buying

Selecting the perfect aluminum tool box goes beyond just choosing a type. Consider these critical features to ensure you get the most value and functionality:

- Gauge of Aluminum: This refers to the thickness of the aluminum. A lower gauge number indicates thicker, more durable metal (e.g., 0.063 vs. 0.080). Thicker aluminum offers greater resistance to dents and provides enhanced security.

- Latching Mechanisms: Look for robust, high-quality latches. Common types include paddle latches (often with push-button release), rotating T-handles, or simple keyed locks. Multiple latch points (especially on longer boxes) enhance security and ensure a tight seal.

- Weather Sealing: A good quality tool box will have a strong rubber gasket or bulb seal around the lid opening. This creates a watertight and dust-proof seal, protecting your contents from the elements.

- Lid Design and Hinges: Full-lid designs offer maximum opening for easy access. Gull-wing lids provide access from either side of the truck. Look for continuous piano hinges or robust stainless steel hinges for smooth operation and durability.

- Gas Struts/Shocks: These hydraulic cylinders assist in opening the lid smoothly and holding it securely in the open position, preventing accidental slamming and making access easier.

- Internal Organization: Some tool boxes come with removable trays, dividers, or built-in compartments to help organize smaller tools and prevent them from rattling around.

- Mounting System: Ensure the box comes with a secure and easy-to-install mounting kit, typically J-hooks that clamp onto the bed rails without drilling, or options for bolting directly to the bed.

- Finish: Common finishes include bright, polished aluminum (diamond plate) or durable black powder-coat. The choice is largely aesthetic, but powder-coat can offer an extra layer of scratch resistance.

Installation Guide: Getting Your Tool Box Set Up

Installing an aluminum tool box is a straightforward process that most truck owners can complete with basic tools.

Tools You’ll Likely Need:

- Socket wrench set or adjustable wrench

- Measuring tape

- Marker or pencil (if marking drilling points)

- Drill (only if permanent mounting is desired, or for specific box types)

Steps for a Crossover Box (Most Common):

- Positioning: Carefully lift the tool box and place it across your truck bed, behind the cab. Ensure it sits squarely and evenly on the bed rails. Adjust its position forward or backward to allow for clearance with the cab or other accessories.

- Access Mounting Points: Open the lid(s) of the tool box to access the internal mounting points, typically located at the front and rear corners of the box.

- Secure with J-Hooks (Non-Drill): Most aluminum crossover boxes come with J-hook clamps.

- Insert the J-hook into the designated slot on the tool box.

- Rotate the hook so the "J" end latches underneath the truck bed rail.

- Tighten the nut on the J-hook with your wrench. Do not overtighten, as this can damage the bed rail or the box. Tighten until snug and the box is stable.

- Repeat for all mounting points (usually 2-4).

- Check Stability: Once all J-hooks are tightened, try to shift the box. It should feel firmly secured with no significant wobble.

- Alternative (Drilling – Less Common for Crossover): Some boxes or specific applications might require drilling through the bed floor for a more permanent, bolt-through installation. If this is the case, carefully measure and mark your drill points, ensure no wires or fuel lines are underneath, and use appropriate hardware with large washers.

Tips for a Secure and Stable Installation:

- Clean Surfaces: Ensure the truck bed rails are clean and free of debris where the box will sit.

- Anti-Slip Mats: Consider placing rubber anti-slip mats under the box’s feet or mounting points to prevent scratching and provide extra grip.

- Load Distribution: When loading the box, try to distribute weight evenly to maintain truck balance.

Maintenance Tips for Longevity

While aluminum tool boxes are low-maintenance, a few simple practices will ensure they last for decades:

- Regular Cleaning: Wash the exterior with mild soap and water, especially after exposure to road salt or harsh chemicals. This prevents grime buildup and preserves the finish.

- Lubricate Latches and Hinges: Periodically apply a silicone-based lubricant or light oil to the hinges and locking mechanisms. This keeps them operating smoothly and prevents corrosion.

- Inspect Weather Seals: Check the rubber seals around the lid(s) for cracks, tears, or compression. Replace them if they are compromised to maintain the waterproof seal.

- Tighten Mounting Hardware: Over time, vibrations can loosen mounting bolts or J-hooks. Periodically check and retighten them to ensure the box remains securely fastened.

Choosing the Right Size and Fit

- Measure Your Truck Bed: Before buying, measure the width of your truck bed (between the rails and across the bed), the depth from the bed rail to the floor, and the length from the cab to your desired position. Pay attention to wheel well obstructions.

- Consider Your Storage Needs: Make a list of the tools and equipment you plan to store. This will help you determine the necessary cubic footage and internal dimensions.

- Compatibility with Other Accessories: If you have a tonneau cover, bed liner, or plan to install one, ensure the tool box you choose is compatible. Some low-profile crossover boxes are designed to work with rolling or folding tonneau covers.

Potential Challenges and Solutions

- Theft: While aluminum boxes are secure, no system is foolproof.

- Solution: Always lock your box. Consider adding an extra padlock for enhanced security. Ensure the mounting system is robust (J-hooks are good, bolt-through is even more secure). Park your truck in well-lit areas.

- Water Leaks: Despite weather seals, leaks can sometimes occur.

- Solution: Inspect the seals regularly. Ensure the box is properly leveled on the bed rails. Check for any small gaps where the box meets the bed. Some owners apply a bead of marine-grade silicone sealant along the base for extra protection.

- Loss of Bed Space: Some larger tool boxes can significantly reduce usable bed space.

- Solution: Choose a box type that balances storage needs with bed space requirements (e.g., side-mount or wheel well boxes for minimal bed intrusion, or a low-profile crossover).

- Rattling: Loose tools or improper mounting can cause rattling.

- Solution: Use foam liners or anti-slip mats inside the box to cushion tools. Double-check all mounting hardware for tightness.

Practical Advice and Actionable Insights

- Assess Your Needs: Before looking at products, clearly define what you need to store, how often you’ll access it, and your budget.

- Read Reviews: Look for reviews from other truck owners regarding specific brands and models. Pay attention to comments on latch quality, weather sealing, and durability.

- Compare Brands: Reputable brands like Weather Guard, UWS, Dee Zee, and Truck Hero are known for quality. Compare their offerings, warranty, and features.

- Don’t Skimp on Security: A tool box is only as good as its lock. Invest in one with robust locking mechanisms.

- Consider Resale Value: A well-maintained aluminum tool box holds its value better than plastic or steel alternatives.

Conclusion

An aluminum tool box for your pickup truck is more than just an accessory; it’s an investment in efficiency, security, and peace of mind. By providing a durable, weather-resistant, and secure sanctuary for your valuable tools and gear, it transforms your truck into a truly functional mobile workstation. From the rugged job site to the weekend adventure, an aluminum tool box ensures your essentials are always organized, protected, and ready for action, allowing you to focus on the task at hand rather than worrying about your equipment. Choose wisely, install correctly, and maintain regularly, and your aluminum tool box will serve as a reliable partner for countless miles and projects to come.

Aluminum Tool Boxes For Pickup Trucks: Estimated Price Guide

Please note: Prices are highly variable based on brand, specific features, aluminum gauge, finish, and retailer. These are estimated ranges for new boxes as of late 2023 / early 2024.

| Tool Box Type | Size Range (Typical) | Key Features (Common) | Estimated Price Range (USD) |

|---|---|---|---|

| Crossover/Cross-Bed | 60-72 inches long, 18-24 inches wide, 12-18 inches high | Single or Gull-Wing Lid, Paddle Latches, Gas Struts, J-Hooks, Diamond Plate or Black Powder-Coat Finish | $350 – $900+ |

| Side-Mount/Saddle | 48-72 inches long, 9-16 inches wide, 9-16 inches high | Single Lid, Keyed Lock, Weather Seal, Mounts on Bed Rail, Often Lower Profile | $250 – $600 |

| Underbody | 24-60 inches long, 12-18 inches deep, 12-18 inches high | Drop-Down Door, T-Handle Latch, Weather Seal, Mounts Under Truck Frame | $300 – $800+ |

| Chest | 36-60 inches long, 18-24 inches wide, 12-20 inches high | Top-Opening Lid, Recessed Latches, Carry Handles, Often Portable | $200 – $550 |

| Wheel Well | 24-36 inches long, 8-12 inches wide, 18-24 inches high | Compact Size, Contoured to Wheel Well, Single Lid, Mounts Directly Over Well | $150 – $400 (per box) |

| Fifth-Wheel | 60-72 inches long, 12-18 inches wide, 8-10 inches high | Low Profile, Recessed Latches, Designed to Clear 5th Wheel Hitch | $400 – $750 |

Frequently Asked Questions (FAQ) About Aluminum Tool Boxes For Pickup Trucks

Q1: Are aluminum tool boxes truly secure against theft?

A1: Aluminum tool boxes offer a high level of security due to their robust construction and quality locking mechanisms (like paddle latches with keys). While no box is 100% impenetrable, they are designed to deter casual theft and significantly slow down determined thieves. Proper installation and using quality padlocks can further enhance security.

Q2: Do aluminum tool boxes rust?

A2: No, aluminum does not rust. Unlike steel, aluminum naturally forms a protective oxide layer when exposed to air, which prevents corrosion. This makes them ideal for outdoor use in all weather conditions.

Q3: How much weight can an aluminum tool box typically hold?

A3: The weight capacity varies greatly depending on the box’s gauge of aluminum, construction, and mounting. Smaller side-mount boxes might hold 50-100 lbs, while large, heavy-duty crossover boxes can safely hold 200-400 lbs or more. Always check the manufacturer’s specifications.

Q4: Can I install an aluminum tool box myself, or do I need professional help?

A4: Most aluminum tool boxes, especially crossover and side-mount types, are designed for DIY installation using simple hand tools like a socket wrench. They often come with J-hook clamps that secure the box without drilling. If drilling is required for your specific box or preferred mounting method, ensure you follow instructions carefully and check for obstructions under the truck bed.

Q5: Will an aluminum tool box affect my truck’s fuel economy?

A5: While any added weight can theoretically impact fuel economy, aluminum is significantly lighter than steel. The impact of an aluminum tool box on fuel economy is usually negligible compared to heavier alternatives or a heavily loaded truck.

Q6: Are aluminum tool boxes waterproof and dustproof?

A6: Quality aluminum tool boxes are designed to be weather-resistant, often featuring durable rubber gaskets or bulb seals around the lid to prevent water and dust intrusion. While most are highly resistant to rain and splashes, none are truly "submersible." Regularly inspecting and maintaining these seals is crucial for optimal protection.

Q7: How do I prevent my tools from rattling inside the box?

A7: To prevent rattling and protect your tools, you can use rubber or foam mat liners at the bottom of the box. Many tool boxes also come with removable trays or dividers that help organize smaller items and keep them secure. You can also use tool wraps or soft bags for individual items.