Welding Trucks For Sale In Texas: Your Comprehensive Guide to Mobile Welding Solutions pickup.truckstrend.com

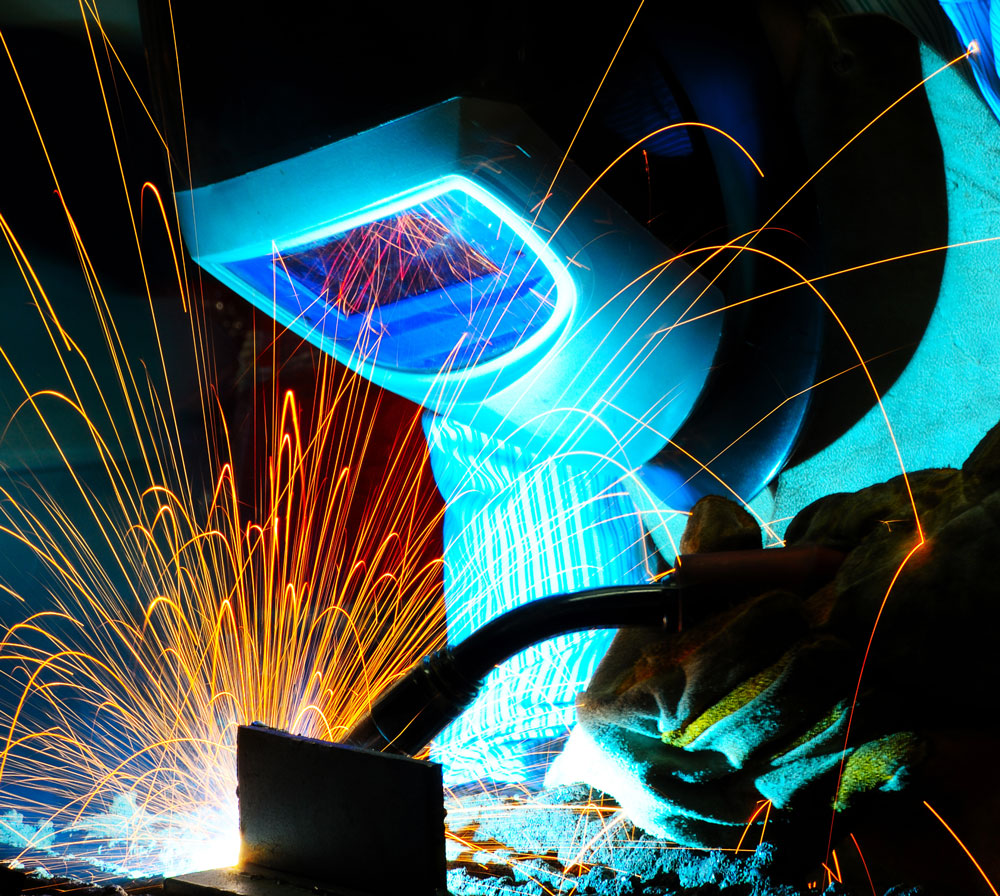

Texas, a state synonymous with vast landscapes, booming industries, and an unrelenting work ethic, is a prime market for specialized commercial vehicles. Among these, the welding truck stands out as an indispensable asset for countless businesses and independent contractors. Far more than just a pickup with a welder in the back, a dedicated welding truck is a self-contained mobile workshop, equipped to handle demanding fabrication, repair, and construction tasks in diverse environments. For professionals in the oil and gas fields, agricultural sectors, bustling construction sites, or critical infrastructure projects across the Lone Star State, owning the right welding truck isn’t just a convenience – it’s a fundamental requirement for productivity, efficiency, and profitability. This comprehensive guide will navigate the intricacies of finding, evaluating, and acquiring welding trucks for sale in Texas, providing invaluable insights for buyers and sellers alike.

Why Texas is the Epicenter for Welding Trucks

Welding Trucks For Sale In Texas: Your Comprehensive Guide to Mobile Welding Solutions

The demand for robust and reliable welding trucks in Texas is unparalleled, driven by a unique confluence of economic and geographical factors:

- Oil and Gas Industry: Texas is the undisputed energy capital of the U.S. From drilling rigs and pipelines to refineries and processing plants, the oil and gas sector constantly requires on-site welding for installation, maintenance, and emergency repairs. Mobile welding units are critical for reaching remote wellheads or addressing urgent issues at sprawling facilities.

- Construction Boom: Major metropolitan areas like Houston, Dallas-Fort Worth, Austin, and San Antonio are experiencing explosive growth, leading to a perpetual demand for commercial, residential, and infrastructure construction. Welders are essential for steel erection, structural repairs, and utility installations, often needing to move between multiple job sites daily.

- Agriculture and Ranching: With vast ranches and agricultural operations, Texas relies on mobile welders for repairing farm equipment, fences, barns, and irrigation systems, often far from a stationary shop.

- Manufacturing and Industrial Maintenance: A diverse manufacturing base, from aerospace to automotive, necessitates specialized welding services for equipment repair, fabrication, and facility upgrades.

- Infrastructure Development: Roads, bridges, ports, and power grids across Texas are continually being built, expanded, and maintained, all requiring the expertise of mobile welding teams.

The sheer scale and diversity of these industries create a vibrant market for new and used welding trucks, making Texas an ideal place to both buy and sell these specialized vehicles.

What Makes a Great Welding Truck? Essential Components Explored

A truly effective welding truck is a carefully configured system designed for rugged reliability and peak performance. Understanding its key components is crucial for making an informed purchase:

1. The Truck Chassis: The Foundation of Mobility

The base vehicle is paramount. Heavy-duty pickup trucks are the most common choice, typically 3/4-ton (e.g., Ford F-250, Ram 2500, Chevy Silverado 2500) or 1-ton (e.g., F-350, Ram 3500, Silverado 3500) and often larger for more specialized applications.

- Payload Capacity: Crucial for carrying the weight of the welder, generator, air compressor, tools, gas bottles, and materials. Exceeding the Gross Vehicle Weight Rating (GVWR) is unsafe and illegal.

- Engine Type: Diesel engines are favored for their torque, durability, and better fuel economy under heavy loads, especially for long-haul or continuous operation. Gasoline engines can be suitable for lighter, less demanding tasks.

- Drivetrain: 4×4 (four-wheel drive) is highly recommended for Texas, particularly for accessing remote job sites in oil fields, unpaved construction areas, or challenging terrain.

- Suspension and Tires: Heavy-duty suspension systems are essential, along with robust tires capable of handling varying road conditions and significant weight.

2. The Welder/Generator: The Heart of the Rig

This is the most critical piece of equipment, providing both welding power and auxiliary electricity.

- Engine-Driven Welders: Top brands include Lincoln Electric (e.g., Vantage, Ranger), Miller Electric (e.g., Trailblazer, Big Blue), and ESAB. These units combine a combustion engine with a welding generator.

- Amperage Output: Ranges from 200-600+ amps, depending on the type of welding (stick, TIG, MIG, flux-cored) and material thickness. Higher amperage allows for more demanding applications.

- AC/DC Capabilities: Most professional welders offer both AC (alternating current) and DC (direct current) outputs, providing versatility for different welding processes and materials.

- Auxiliary Power: Many units provide AC generator power (e.g., 10,000-20,000 watts) to run grinders, plasma cutters, lights, and other power tools, eliminating the need for separate generators.

- Arc Characteristics and Features: Look for features like arc force control, digital meters, and multi-process capabilities.

3. The Welding Bed/Body: The Mobile Workshop

The bed is designed for functionality, organization, and safety.

- Service Body (Utility Body): Features multiple lockable compartments along the sides, ideal for organized storage of tools, consumables, and safety gear. Often includes an open cargo area in the middle.

- Flatbed: Offers maximum flexibility for hauling large items, but requires additional aftermarket toolboxes and storage solutions.

- Material: Steel is durable and common; aluminum is lighter, offering better fuel economy and payload capacity, but typically costs more.

- Crane/Lift: Many heavy-duty rigs include a small crane or boom lift for handling heavy materials, large gas cylinders, or equipment.

- Pipe Racks: Essential for transporting pipes, conduit, or structural steel.

- Bottle Racks: Secure storage for oxygen, acetylene, argon, and other gas cylinders.

4. Tool Storage & Organization

Efficiency on a job site depends on quick access to tools and consumables.

- Lockable Compartments: Crucial for securing expensive tools and preventing theft.

- Drawers and Bins: For small parts, electrodes, and fittings.

- Work Benches and Vises: Integrated or portable, providing a stable surface for preparation and fabrication.

5. Other Essential Accessories

- Air Compressor: For running pneumatic tools, plasma cutters, and inflating tires.

- Cutting Torches: Oxygen-acetylene setups are standard.

- Grinders and Plasma Cutters: Essential for material preparation and cutting.

- Work Lights: Powerful LED lighting for nighttime or low-light conditions.

- Safety Equipment: Fire extinguishers, first-aid kits, PPE storage.

- Grounding Clamps and Cable Storage: Organized and easily accessible.

Where to Find Welding Trucks For Sale in Texas

The Texas market offers a variety of avenues for purchasing a welding truck:

- Online Marketplaces:

- Commercial Truck Specific Sites: TruckPaper.com, CommercialTruckTrader.com, MyLittleSalesman.com are excellent resources for new and used commercial vehicles, including specialized welding rigs.

- General Classifieds: Craigslist, Facebook Marketplace can yield local private sales, but require caution due to potential scams and less transparency.

- Auction Sites: eBay Motors occasionally lists welding trucks.

- Dealerships:

- New Commercial Truck Dealerships: Many dealerships specializing in Ford, Ram, or GM heavy-duty trucks offer custom-built or upfitted welding rigs.

- Used Commercial Truck Dealers: Often have a wide selection of pre-owned welding trucks, sometimes from fleet sales.

- Specialized Welding Equipment Dealers: Companies like Texas AirGas, Praxair, or local welding supply stores sometimes sell complete used rigs or can guide you to reputable sellers.

- Auctions:

- Industrial Auctions: Ritchie Bros. Auctioneers, IronPlanet, and other industrial auction houses frequently have heavy equipment sales that include welding trucks, especially those from large companies or government entities.

- Local Government/Utility Auctions: Cities, counties, and utility companies often sell off their older fleet vehicles, which may include welding trucks.

- Private Sellers:

- Networking: Word-of-mouth within the welding community, industry forums, and local trade shows can lead to private sales.

- Fleet Sales: Larger welding or construction companies sometimes sell off their older rigs as they upgrade their fleets.

Key Considerations When Buying a Used Welding Truck

Purchasing a used welding truck can offer significant cost savings, but it requires diligent inspection and research:

- Budget and ROI: Determine your maximum budget, considering not just the purchase price but also potential repairs, upgrades, and ongoing maintenance. Calculate the potential return on investment (ROI) for your business.

- Truck Condition (Chassis):

- Engine and Transmission: Check for leaks, unusual noises, excessive smoke, and smooth shifting. Request maintenance records.

- Mileage and Hours: High mileage isn’t necessarily a deal-breaker for a well-maintained diesel, but verify engine hours on the welder unit itself, as this indicates actual work performed.

- Frame and Suspension: Inspect for rust, cracks, or signs of accident damage. Ensure the suspension isn’t sagging due to overloading.

- Tires and Brakes: Assess wear and tear. These can be significant replacement costs.

- Welding Equipment Condition:

- Functionality: Test the welder extensively. Run it through various processes (stick, MIG, TIG if applicable), test auxiliary power outlets, and ensure all controls work.

- Engine Hours: Separate from truck mileage, the welder engine hours are critical. Lower hours typically mean more life left.

- Maintenance History: Ask for service records for the welder unit.

- Output Consistency: Check for stable arc performance.

- Body and Storage: Inspect compartments for damage, rust, and functionality of latches and locks. Ensure bottle racks are secure.

- Payload and GVWR: Verify the truck’s GVWR and ensure the current setup (and your intended load) does not exceed it. Overloading is a common issue and can lead to safety hazards and legal penalties.

- Customization Needs: Does the existing setup meet your specific welding requirements, or will you need to invest in significant modifications?

- Professional Inspection: Always, always, always get a pre-purchase inspection by an independent, qualified mechanic and a welding equipment technician. This investment can save you from costly surprises.

- Title and Liens: Verify that the seller has a clear title and that there are no outstanding liens on the vehicle or equipment.

Financing Your Welding Truck Purchase

Securing financing is a crucial step for many buyers:

- Traditional Bank Loans: Banks and credit unions offer commercial vehicle loans. You’ll typically need good credit and a solid business plan.

- Equipment Financing Companies: Specialized lenders focus on equipment loans, often with more flexible terms than traditional banks, especially for used equipment.

- SBA Loans: Small Business Administration (SBA) loans can offer favorable terms for small businesses, including equipment purchases.

- Dealership Financing: Some larger dealerships offer in-house financing or work with preferred lenders.

Tips for Selling Your Welding Truck in Texas

If you’re looking to sell your welding truck in the Texas market, these tips can help maximize its value and ensure a smooth transaction:

- Prepare the Truck: Thoroughly clean the truck inside and out. Organize and clean all compartments. Address minor repairs (e.g., faulty lights, sticky latches). A well-presented truck instills confidence.

- Service and Maintain: Have recent service records for both the truck and the welder unit. A fresh oil change or a recent welder service can be a strong selling point.

- Detailed Listing with High-Quality Photos:

- Take numerous clear, well-lit photos from all angles, including close-ups of the welder, compartments, and any unique features.

- Provide a comprehensive description: year, make, model, mileage, engine type, welder make/model/hours, type of bed, accessories (crane, air compressor, etc.), recent maintenance, and any known issues.

- Be transparent about wear and tear; it builds trust.

- Research Market Value: Look at similar welding trucks for sale in Texas to price your unit competitively. Consider age, condition, equipment, and hours.

- Market Broadly: Utilize multiple platforms: online commercial truck sites, social media groups, local classifieds, and industry forums.

- Be Responsive and Available: Promptly respond to inquiries and be flexible for showings and inspections.

- Have Documentation Ready: Title, maintenance records, and any manuals should be organized and ready for the buyer.

Estimated Price Guide for Welding Trucks For Sale In Texas

Please note: Prices for welding trucks vary significantly based on the truck’s year, make, model, mileage, overall condition, the specific welder unit installed (make, model, hours), the type of service body, and additional accessories. This table provides broad estimates for used welding trucks in Texas, assuming a functional and well-equipped rig.

| Truck Type & Chassis (Example) | Year Range | Condition | Key Equipment Included (Example) | Estimated Price Range (USD) | Notes |

|---|---|---|---|---|---|

| Light-Duty Rig | 2010-2016 | Good Used | Ford F-250/Ram 2500/Silverado 2500, Gas Engine, Service Body, Miller Trailblazer 302/Lincoln Ranger 250/305G | $25,000 – $45,000 | Lower hours on welder, decent truck mileage. Suitable for light-to-medium fabrication. |

| Medium-Duty Rig | 2014-2019 | Very Good | Ford F-350/Ram 3500/Silverado 3500, Diesel Engine, Service Body, Lincoln Vantage 300/400, Air Compressor | $45,000 – $75,000 | Well-maintained, moderate truck mileage, professional-grade setup. Common for pipeline/field work. |

| Heavy-Duty Rig | 2017-2022 | Excellent | Ford F-450/F-550/Ram 4500/5500, Diesel Engine, Custom Service Body, Lincoln Vantage 500/Miller Big Blue 500, Crane/Lift, Integrated Air Compressor | $75,000 – $120,000+ | Low mileage, newer equipment, often includes advanced features. Ideal for heavy industrial/structural. |

| Older/Basic Setup | 2005-2012 | Fair | Mixed Brands, Flatbed w/ Toolboxes, Older Engine-Driven Welder (e.g., Lincoln SA-200/250) | $15,000 – $25,000 | Higher mileage, cosmetic wear, but still functional. Good for entry-level or specific niche work. |

Disclaimer: These are rough estimates. Actual prices can be higher or lower depending on exact specifications, hours on equipment, specific market demand at the time of sale, and the negotiation process.

Frequently Asked Questions (FAQ) About Welding Trucks in Texas

Q1: What’s the best truck size for a welding rig in Texas?

A1: For most professional welders in Texas, a 1-ton (e.g., F-350, Ram 3500, Silverado 3500) or larger heavy-duty pickup is recommended. This provides the necessary payload capacity for the welder, tools, gas bottles, and materials without exceeding the GVWR. A 4×4 drivetrain is highly advisable for navigating diverse Texas terrain.

Q2: Should I buy a new or used welding truck?

A2: Buying new offers warranties and the latest technology but comes at a significant premium. Used trucks offer substantial cost savings and can be excellent value if thoroughly inspected. The choice depends on your budget, immediate business needs, and risk tolerance. Many successful welders start with a well-maintained used rig.

Q3: What’s the most important piece of equipment on a welding truck?

A3: While the truck chassis is critical for mobility, the engine-driven welder/generator is the heart of the operation. Its reliability, power output, and features directly impact your ability to complete jobs effectively. Invest in a reputable brand with sufficient amperage and auxiliary power.

Q4: How do I finance a welding truck purchase?

A4: Options include traditional bank loans, credit unions, specialized equipment financing companies, and SBA loans. For used trucks, equipment financing companies are often a good choice due to their flexibility. Always compare interest rates and terms from multiple lenders.

Q5: Are there any special permits or licenses required to operate a welding truck in Texas?

A5: For most standard welding trucks (non-CDL), no special welding-specific permits are required beyond a standard driver’s license. However, you must adhere to all DOT regulations regarding vehicle weight (GVWR), safety equipment, and securement of loads. If your truck and equipment exceed certain weight thresholds, a Commercial Driver’s License (CDL) might be necessary. Always check Texas DOT regulations.

Q6: What are common maintenance issues to watch for in a used welding truck?

A6: Beyond standard vehicle maintenance (engine, transmission, brakes, tires), pay attention to:

- Welder Unit: Hours on the engine, consistent output, proper function of all controls, condition of welding cables.

- Auxiliary Power: Functionality of all outlets.

- Body: Rust in compartments, broken latches, cracks in the bed.

- Air Compressor: Leaks, proper pressure buildup, function of dryer (if equipped).

- Crane/Lift: Smooth operation, no hydraulic leaks, current certification (if applicable).

Conclusion

The market for welding trucks for sale in Texas is as vast and dynamic as the state itself. For welders and fabrication businesses, a well-equipped welding truck is more than just a vehicle; it’s a mobile command center that empowers them to seize opportunities across diverse industries. Whether you’re a seasoned professional seeking an upgrade or a burgeoning entrepreneur embarking on your mobile welding journey, understanding the nuances of these specialized vehicles, from their essential components to the intricacies of the buying and selling process, is paramount. By leveraging this guide, conducting thorough research, and prioritizing comprehensive inspections, you can confidently navigate the Texas market, secure a reliable asset, and ensure your mobile welding operation is ready to tackle any challenge the Lone Star State throws its way. Your next successful job in Texas might just be a welding truck away.

/welder-using-an-oxy-acetylene-cutting-torch-139097938-5772b0073df78cb62c8b1542.jpg)