Septic Tank Pumping Trucks For Sale: Your Comprehensive Guide to Entering or Expanding the Septic Service Business pickup.truckstrend.com

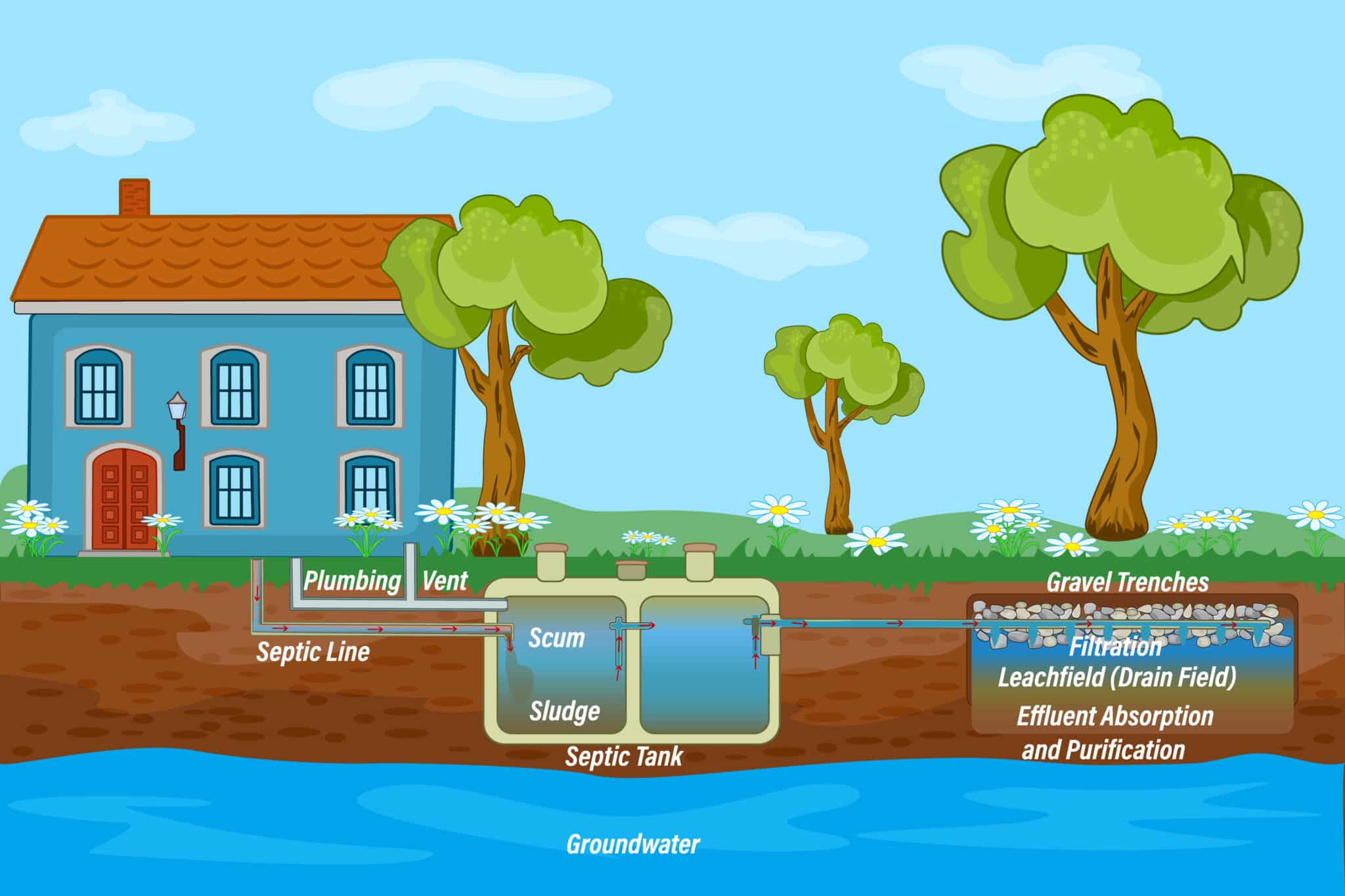

The unseen backbone of modern sanitation, septic tank pumping trucks are indispensable vehicles critical for maintaining public health and environmental integrity in areas without centralized sewer systems. Far more than just a truck with a tank, these specialized machines are engineered to safely and efficiently remove liquid and solid waste from septic tanks, grease traps, and portable toilets. For entrepreneurs looking to enter the lucrative waste management industry, established businesses aiming to expand their fleet, or municipalities seeking to enhance their public services, understanding the nuances of "Septic Tank Pumping Trucks For Sale" is the first step towards a successful investment.

This comprehensive guide will navigate the landscape of buying a septic pumping truck, offering insights into types, key components, crucial considerations, practical tips for purchase, and a look at market pricing.

Septic Tank Pumping Trucks For Sale: Your Comprehensive Guide to Entering or Expanding the Septic Service Business

Understanding the Septic Pumping Truck Market

The demand for septic pumping services is consistently robust, driven by the continuous growth of suburban and rural communities, aging septic systems requiring regular maintenance, and the ubiquitous presence of portable toilets at construction sites and events. This steady demand ensures a viable market for those operating these essential vehicles.

Buyers in this market typically fall into a few categories:

- Start-up Businesses: Individuals or small teams looking to establish a new septic service company. They often seek cost-effective, reliable used trucks to minimize initial overhead.

- Established Companies: Existing septic or waste management businesses aiming to expand their service capacity, replace aging vehicles, or diversify into related services like grease trap cleaning or portable toilet rentals. They might consider new or higher-end used trucks.

- Municipalities and Government Agencies: Public works departments that manage their own waste treatment facilities or provide direct services to their constituents. Their purchases often prioritize durability, long-term cost-efficiency, and specific regulatory compliance.

Regardless of the buyer type, the objective remains the same: acquire a dependable workhorse that can handle the demanding nature of waste removal, ensuring efficiency, safety, and profitability.

Key Components of a Septic Tank Pumping Truck

A septic tank pumping truck is a sophisticated piece of machinery, and understanding its core components is vital for making an informed purchasing decision.

- The Chassis (The Truck Itself): This is the foundation, comprising the engine, transmission, frame, axles, and cab. Common chassis manufacturers include Freightliner, International, Peterbilt, Kenworth, Mack, and Ford. The choice of chassis impacts reliability, fuel efficiency, maintenance costs, and driver comfort. Consider the truck’s Gross Vehicle Weight Rating (GVWR) to ensure it can legally and safely carry the desired tank capacity when full.

- The Vacuum Pump: This is the heart of the system, creating the vacuum that sucks waste into the tank.

- Rotary Vane Pumps: Most common, reliable, and come in various sizes (measured in CFM – Cubic Feet per Minute). Brands like Masport, Moro, and Jurop are industry standards.

- Liquid Ring Pumps: Offer higher vacuum levels and cooler operation, suitable for heavy-duty, continuous use, and often found in industrial applications.

- Piston Pumps: Less common for septic, but used in some high-pressure, high-flow applications.

The pump’s CFM rating dictates how quickly the tank can be filled. Higher CFM means faster pumping, which translates to more jobs per day.

- The Tank: This is where the waste is stored.

- Material:

- Steel: Most common, durable, but susceptible to corrosion over time, especially with acidic waste. Often coated internally.

- Aluminum: Lighter, corrosion-resistant, but more expensive and potentially less robust against physical damage. Ideal for maximizing payload capacity on weight-restricted roads.

- Stainless Steel: Highly corrosion-resistant, durable, and suitable for a wider range of waste types, but the most expensive option.

- Capacity: Ranges from smaller 500-gallon units for portable toilet servicing to massive 5,000+ gallon tanks for large commercial septic systems or municipal work. Matching capacity to your typical job size minimizes trips to the disposal site.

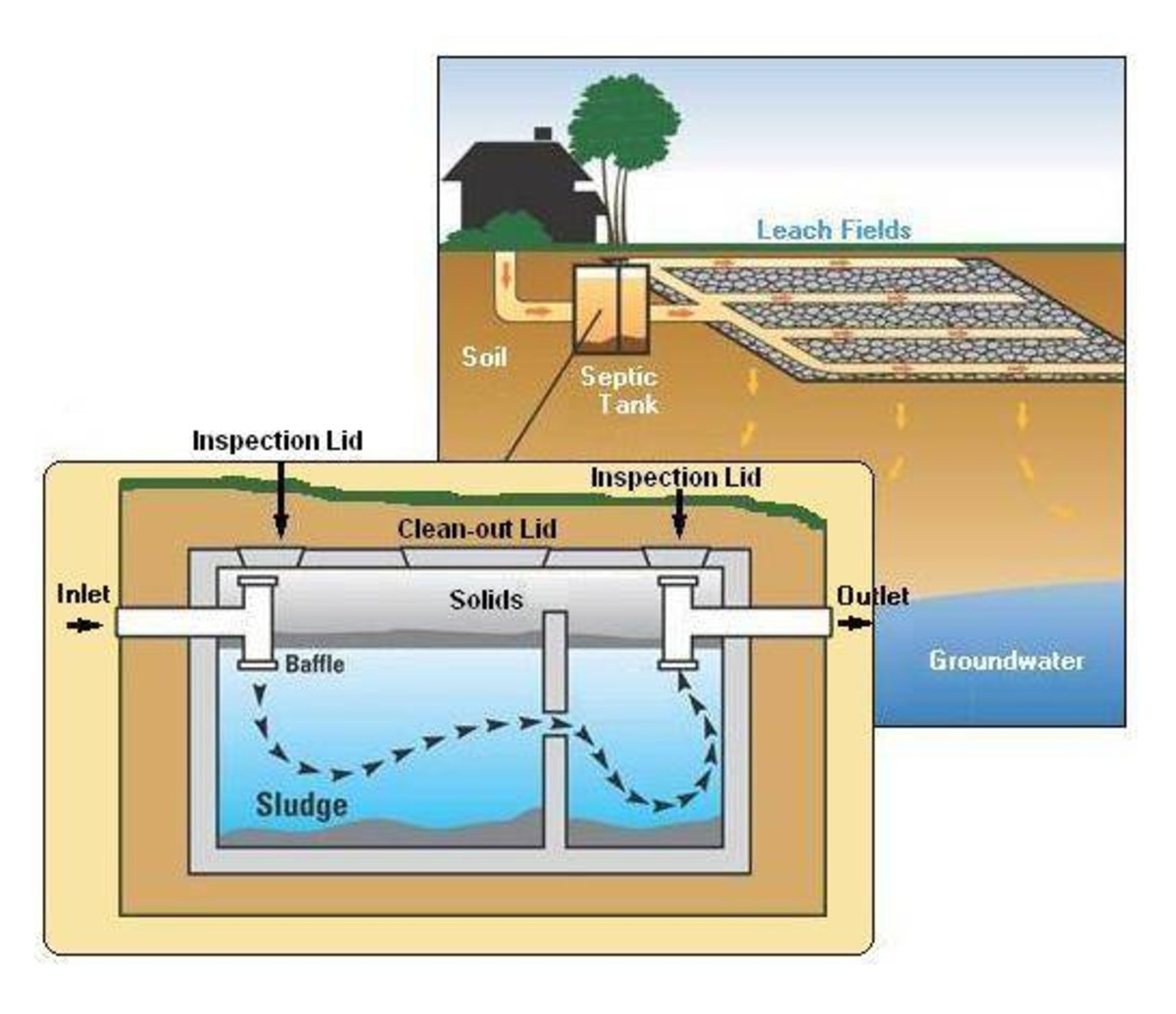

- Features: Look for baffles (to prevent sloshing), sight glasses (to monitor fill levels), full-opening rear doors (for easy cleaning), and robust valve systems.

- Material:

- Power Take-Off (PTO) System: This mechanism transfers power from the truck’s engine to drive the vacuum pump. It’s crucial that the PTO is correctly matched to the transmission and pump for optimal performance.

- Hoses and Accessories: Suction hoses (typically 3-4 inches in diameter), discharge hoses, nozzles, quick-connect fittings, and storage racks are all essential. Ensure the hoses are of adequate length and condition, especially if buying used.

Types of Septic Pumping Trucks For Sale

The market offers a spectrum of options, each with its own advantages and disadvantages:

-

New Septic Pumping Trucks:

- Pros: Latest technology, full manufacturer warranty on both chassis and vacuum system, customizable to exact specifications, higher reliability, and often better fuel efficiency.

- Cons: Significant upfront cost, can have a long lead time for custom builds.

- Ideal For: Established businesses with capital, those needing highly specific configurations, or companies prioritizing long-term reliability and minimal downtime.

-

Used Septic Pumping Trucks:

- Pros: Substantially lower purchase price, immediate availability, allows smaller businesses to enter the market. Depreciation has already occurred, potentially offering better value.

- Cons: Higher risk of mechanical issues, no warranty (or very limited), potential for hidden problems, may require immediate repairs or upgrades. Fuel efficiency might be lower, and older emissions standards might apply.

- Ideal For: Start-ups with limited budgets, businesses looking for a temporary expansion vehicle, or those comfortable with potential maintenance.

-

Refurbished or Rebuilt Septic Trucks:

- Pros: A middle ground offering updated components (new pump, refurbished tank, engine overhaul) on a used chassis. Can come with a limited warranty on rebuilt components, providing more reliability than a "straight used" truck at a lower cost than new.

- Cons: Still a used chassis, so other components might fail. Cost can approach that of a basic new model.

- Ideal For: Buyers seeking a balance between cost-effectiveness and reliability, or those who want a truck that’s "ready to work" without major immediate overhauls.

-

Specialized Pumper Trucks:

- Portable Toilet Service Trucks: Smaller tanks (500-1000 gallons), often with a separate freshwater tank for rinsing, and multiple compartments for supplies. Designed for agility and frequent stops.

- Combination Vacuum/Jetting Trucks: Equipped with both vacuum capabilities and high-pressure water jetting systems for clearing clogs in sewer lines or septic fields. Highly versatile but more complex and expensive.

Important Considerations When Buying

A well-thought-out purchase strategy is crucial to avoid costly mistakes.

- Budget and Financing: Determine your maximum budget. Explore financing options such as traditional bank loans, equipment leasing, or manufacturer financing. Factor in not just the purchase price, but also taxes, registration, insurance, and initial maintenance.

- Tank Capacity vs. Business Needs: Match the tank size to your typical job. A 2,000-gallon truck is versatile for residential, while larger 3,000-5,000 gallon trucks are better for commercial or municipal contracts. Over-specifying can lead to unnecessary costs and decreased maneuverability.

- Pump Type and CFM: A higher CFM pump means faster service times, but also higher initial cost and potentially more fuel consumption. Evaluate if the increased speed justifies the added expense for your projected workload.

- Truck Condition (Especially for Used):

- Engine & Transmission: Look for leaks, strange noises, or excessive smoke. Check fluid levels and color. Test drive the truck under various conditions.

- Frame & Suspension: Inspect for cracks, rust, or signs of heavy damage.

- Tires & Brakes: Critical safety components. Check tire tread depth and brake pad wear.

- Electrical System: Test all lights, gauges, and auxiliary functions.

- Tank Integrity:

- External: Look for dents, patches, or excessive rust.

- Internal: If possible, inspect the inside for severe corrosion or pitting, especially at the bottom. Check the integrity of baffles and welds.

- Valves & Hoses: Ensure all valves operate smoothly and hoses are free from cracks or significant wear.

- Regulatory Compliance: Research local, state, and federal regulations regarding waste transportation, disposal, vehicle emissions, and weight limits. Ensure the truck meets all necessary standards and that you have the required permits and licenses.

- Maintenance History: For used trucks, a detailed maintenance log is invaluable. It indicates how well the previous owner cared for the vehicle and helps predict future maintenance needs.

- Parts Availability & Service Network: Choose a truck (chassis and vacuum system) for which parts are readily available and a reliable service network exists in your area. Downtime due to parts scarcity can be extremely costly.

- Resale Value: Certain brands and configurations hold their value better than others. Consider this if you plan to upgrade or sell the truck in the future.

Tips for Finding and Purchasing Your Septic Pumping Truck

- Where to Look:

- Specialized Dealerships: Dealers focusing on new and used vacuum trucks often have knowledgeable staff and a good selection.

- Online Marketplaces: Websites like TruckPaper.com, CommercialTruckTrader.com, MyLittleSalesman.com, and eBay Motors are excellent resources for finding used trucks nationwide.

- Auctions: Equipment auctions can offer good deals, but require quick decision-making and thorough pre-inspection.

- Industry Associations & Forums: Networking with other septic professionals can lead to private sales.

- Direct from Businesses: Some companies sell off older fleet vehicles directly.

- Thorough Inspection: Never buy sight unseen. If buying used, have a qualified heavy-duty mechanic perform a pre-purchase inspection. This can uncover hidden issues and save you thousands in future repairs.

- Test Drive: Drive the truck under various conditions – empty and, if possible, with some weight (simulating a partial load) – to assess engine performance, transmission shifts, brakes, and steering.

- Negotiation: Don’t be afraid to negotiate the price. Research comparable sales to understand fair market value.

- Legalities: Ensure all paperwork is in order: clear title, bill of sale, and any necessary transfer documents. Understand sales tax implications.

- Insurance: Secure appropriate commercial vehicle insurance before taking possession of the truck.

Challenges and Solutions

- High Upfront Cost:

- Solution: Start with a well-inspected used truck, explore financing options, or consider leasing to spread out the cost.

- Maintenance and Downtime:

- Solution: Implement a rigorous preventative maintenance schedule. Build a relationship with a reliable heavy-duty mechanic. Keep essential spare parts on hand.

- Regulatory Hurdles:

- Solution: Proactively research and understand all local, state, and federal regulations before purchasing. Work with experienced brokers or consultants if needed.

- Finding the Right Fit:

- Solution: Clearly define your business model and anticipated workload before you start shopping. Don’t buy more truck than you need, but also ensure it can handle future growth.

Septic Tank Pumping Trucks For Sale: Estimated Price Guide

Please note: Prices for septic tank pumping trucks vary drastically based on the truck’s year, make, model, condition, tank material and capacity, pump type and age, mileage, and included features. This table provides estimated ranges for general guidance. Always conduct thorough research and inspections.

| Category | Tank Capacity (Gallons) | Chassis Type (Examples) | Estimated Price Range (USD) | Key Features/Notes |

|---|---|---|---|---|

| Used (Entry-Level) | 1,000 – 2,500 | Older Ford, International | $25,000 – $60,000 | Older model year (10+ years), higher mileage, potentially visible wear and tear. Good for start-ups on a tight budget. Expect some immediate maintenance. Often steel tanks. |

| Used (Mid-Range) | 2,500 – 4,000 | Freightliner, Peterbilt | $60,000 – $150,000 | Mid-range model year (5-10 years), moderate mileage. Generally well-maintained, but may have minor issues. Good balance of cost and reliability. Often steel or aluminum tanks. |

| Used (Premium) | 4,000 – 5,000+ | Kenworth, Mack, Peterbilt | $150,000 – $250,000+ | Newer model year (3-5 years), lower mileage. Excellent condition, possibly with upgraded features (e.g., higher CFM pump, stainless steel tank, jetting combo). Near-new performance without the full new price tag. |

| Refurbished/Rebuilt | 2,500 – 4,500 | Various | $100,000 – $200,000 | Used chassis with new or rebuilt vacuum pump, newly painted/lined tank, and often refreshed mechanical components. Offers a blend of reliability and value. Specific components often have a limited warranty. |

| New | 2,000 – 5,000+ | Freightliner, Peterbilt | $250,000 – $450,000+ | Custom-built to specifications. Latest technology, full warranties, highest reliability, and maximum lifespan. Can be tailored for specific applications (e.g., portable restroom service, grease trap, industrial waste). Price varies greatly by customization. |

| Portable Restroom Service Truck | 500 – 1,000 (waste) + 200-500 (fresh) | Ford F-Series, Isuzu | $50,000 – $150,000 (New) | Smaller, more agile. Includes separate freshwater tank for rinsing, multiple compartments for supplies. Designed for high volume of smaller jobs. |

Frequently Asked Questions (FAQ)

Q1: What’s the typical lifespan of a septic pumping truck?

A1: With proper maintenance, the chassis can last 15-20 years or more (300,000 – 500,000+ miles), while the vacuum system (tank and pump) can last equally long, or even longer if components are replaced/rebuilt periodically.

Q2: Can I convert a regular truck into a pumper truck?

A2: While technically possible, it’s highly complex, expensive, and not recommended for commercial operation. It requires significant structural modifications to the chassis, installation of a PTO, vacuum pump, and a specialized tank. It’s almost always more cost-effective and safer to buy a purpose-built truck.

Q3: What licenses do I need to operate a septic truck?

A3: This varies by location. You’ll likely need a commercial driver’s license (CDL) if the truck’s GVWR exceeds certain limits. Additionally, your business will need specific waste hauler permits, environmental licenses, and potentially local business licenses. Always check with your state’s Department of Transportation (DOT) and environmental protection agencies.

Q4: How often do vacuum pumps need maintenance?

A4: This depends on the pump type and usage, but generally, regular oil changes (for vane pumps), filter checks, and inspections of hoses and fittings are recommended every 200-500 operating hours or as per manufacturer guidelines. Neglecting maintenance can lead to costly pump failure.

Q5: What’s the difference between steel and aluminum tanks?

A5: Steel tanks are heavier, more durable against impact, and typically less expensive, but they are susceptible to rust and corrosion, especially from acidic waste. Aluminum tanks are lighter (allowing for greater payload), corrosion-resistant, and have a longer lifespan without internal lining issues, but they are more expensive and can be more prone to denting. Stainless steel offers the best corrosion resistance but at the highest cost.

Q6: Is it better to buy a new or used septic truck?

A6: There’s no single "better" option; it depends on your budget, business goals, and risk tolerance. New trucks offer reliability and warranties but come at a high cost. Used trucks are more affordable but carry higher risks of maintenance issues. Refurbished trucks offer a good compromise. For start-ups, a well-inspected used truck is often the most practical entry point.

Conclusion

Investing in a septic tank pumping truck is a significant decision that requires careful consideration and thorough research. Whether you’re a budding entrepreneur or an established company, selecting the right vehicle is paramount to operational efficiency, profitability, and long-term success in the waste management industry. By understanding the key components, exploring the various types of trucks available, diligently evaluating important considerations, and applying practical buying tips, you can confidently navigate the "Septic Tank Pumping Trucks For Sale" market.

Remember, a well-chosen septic truck isn’t just a piece of equipment; it’s the foundation of a vital service that contributes to public health and environmental stewardship. Choose wisely, maintain diligently, and your investment will serve your business and community for years to come.