Ready Mix Concrete Trucks For Sale: Your Comprehensive Guide to Acquisition pickup.truckstrend.com

In the bustling world of construction, where foundations are laid and structures rise, the ready mix concrete truck stands as an undisputed workhorse. More than just a vehicle, it’s a mobile concrete plant, delivering the lifeblood of countless projects directly to the point of pour. For businesses, contractors, or even ambitious individuals looking to enter the lucrative concrete supply industry, the decision to invest in a ready mix concrete truck is a pivotal one. This comprehensive guide, "Ready Mix Concrete Trucks For Sale," will navigate you through every critical aspect of acquiring this essential piece of heavy machinery, ensuring your investment is both sound and successful.

Understanding the Heartbeat of Construction: What is a Ready Mix Concrete Truck?

Ready Mix Concrete Trucks For Sale: Your Comprehensive Guide to Acquisition

A ready mix concrete truck, often simply called a concrete mixer or cement mixer, is a specialized vehicle designed to transport and agitate concrete from a batching plant to a construction site. Its primary function is to ensure the concrete remains in a plastic, workable state until it is discharged. This is achieved by a continuously rotating drum, which prevents the concrete from setting prematurely and maintains a homogenous mixture.

The core components of a ready mix truck include a robust chassis (the truck frame), a powerful engine, a rotating mixer drum, a water tank for adding water or washing out, and a series of chutes for controlled discharge. Unlike on-site mixing, which can be inconsistent and labor-intensive, ready mix concrete is batched precisely in a plant, ensuring consistent quality, strength, and workability. For any operation requiring reliable, high-volume concrete delivery, these trucks are not just beneficial; they are indispensable.

The Indispensable Benefits of Owning a Ready Mix Concrete Truck

Acquiring a ready mix concrete truck offers a multitude of advantages that can significantly impact a construction business’s efficiency, profitability, and project capacity.

- Unparalleled Efficiency and Speed: Ready mix trucks deliver concrete directly to the job site, eliminating the time-consuming and labor-intensive process of on-site mixing. This accelerates project timelines, allowing for quicker turnaround on pours.

- Superior Quality Control: Concrete batched at a plant is produced under controlled conditions, ensuring precise proportions of cement, aggregates, water, and admixtures. The continuous agitation during transit maintains this consistency, leading to higher quality, more reliable concrete for your projects.

- Reduced Labor Costs: By outsourcing the mixing process, you significantly reduce the need for on-site labor dedicated to concrete production. This frees up your workforce for other critical tasks, optimizing overall project costs.

- Versatility Across Project Sizes: Ready mix trucks come in various capacities, making them suitable for anything from small residential slabs to large-scale commercial foundations. Owning a fleet or selecting the right capacity allows you to tackle diverse projects.

- Increased Project Scalability: With the ability to deliver concrete reliably and efficiently, businesses can take on more projects simultaneously, expanding their operational capacity and revenue potential.

- Profit Potential: For concrete suppliers, owning these trucks is their core business. For contractors, it can mean savings on concrete costs, better control over delivery schedules, and even the opportunity to supply concrete to other smaller contractors.

Navigating the Market: Types of Ready Mix Concrete Trucks Available for Sale

When searching for ready mix concrete trucks for sale, you’ll encounter various options primarily differentiated by their condition, capacity, and manufacturer.

-

New Ready Mix Concrete Trucks:

- Pros: Come with manufacturer warranties, incorporate the latest technology (e.g., fuel efficiency, emissions control), offer maximum reliability, and allow for customization of features.

- Cons: Significantly higher upfront cost, longer lead times for delivery if custom-ordered.

- Ideal for: Large-scale operations, businesses prioritizing cutting-edge technology and long-term reliability, or those with substantial capital investment.

-

Used Ready Mix Concrete Trucks:

- Pros: Substantially lower purchase price, immediate availability, and a wider range of options from various model years. Can offer excellent value if chosen wisely.

- Cons: No warranty (or limited), potential for wear and tear, higher maintenance costs down the line, and may not feature the latest technological advancements.

- Ideal for: Start-up businesses, those with a tighter budget, or operations needing additional capacity without a major capital outlay.

-

Drum Capacity: The capacity of the mixer drum is measured in cubic yards (or cubic meters). Common sizes include 6, 8, 10, and 12 cubic yards. Choosing the right capacity depends on your typical project size and concrete volume requirements. Smaller trucks are more maneuverable in tight spaces, while larger ones offer greater efficiency for big pours.

-

Chassis and Mixer Manufacturers: The market features several reputable manufacturers for both the truck chassis and the mixer drum.

- Chassis Brands: Mack, Kenworth, Peterbilt, Freightliner, Volvo, International, Sterling.

- Mixer Drum Brands: McNeilus, Con-Tech, London Machinery, Terex, Oshkosh, Cifa, Putzmeister.

- Researching the reputation, parts availability, and service network for both the chassis and mixer components is crucial.

Key Considerations Before Making Your Purchase

A concrete truck is a significant investment. Thorough due diligence is essential to ensure you make an informed decision.

- Budget and Financial Planning: Beyond the purchase price, factor in operating costs (fuel, oil, tires), insurance, registration, and ongoing maintenance. Explore financing options such as loans, leases, or lease-to-own agreements.

- Project Needs and Operational Scale: Analyze your typical concrete volume, frequency of pours, and the terrain of your job sites. A larger fleet or specific truck types might be needed for diverse or high-volume operations.

- Maintenance History and Condition (for Used Trucks): This is paramount. Request detailed service records, engine hours, and mileage. Inspect the mixer drum for excessive wear, cracks, or hardened concrete buildup. Check the chassis for rust, frame damage, and tire condition. A pre-purchase inspection by a qualified mechanic is highly recommended.

- Regulatory Compliance: Be aware of local, state, and federal regulations regarding vehicle weight limits, emissions standards (e.g., EPA compliance, DEF systems for newer trucks), and safety requirements. Non-compliance can lead to hefty fines and operational disruptions.

- Local Support and Parts Availability: Ensure that parts for your chosen make and model are readily available and that authorized service centers are accessible in your operating region. Downtime due to parts scarcity can be extremely costly.

- Resale Value: Consider the long-term value of the truck. Reputable brands with good maintenance records generally hold their value better, which is important if you plan to upgrade or sell in the future.

Tips for a Successful Ready Mix Concrete Truck Acquisition

Making a smart purchase requires more than just knowing what to look for; it involves a strategic approach.

- Thorough Inspection is Non-Negotiable: For used trucks, visually inspect every component: engine, transmission, brakes, tires, suspension, hydraulic systems, and electrical wiring. Pay close attention to the mixer drum’s condition, including the fins, barrel integrity, and washout system. Look for signs of leaks or excessive wear.

- Test Drive: Always test drive the truck, ideally with a load (if safe and permissible). Listen for unusual noises from the engine or transmission, check brake performance, and assess steering responsiveness. Operate the mixer drum to ensure it rotates smoothly in both directions.

- Fluid Analysis: For used trucks, consider getting a professional fluid analysis of engine oil, transmission fluid, and hydraulic fluid. This can reveal underlying mechanical issues not visible during a standard inspection.

- Review Documentation: Verify the truck’s title, registration, and any available service or maintenance records. Confirm the VIN matches all documents.

- Negotiate Wisely: Don’t hesitate to negotiate the price, especially for used trucks. Be prepared to walk away if the deal doesn’t feel right or if the seller isn’t transparent.

- Explore Financing Options: Consult with financial institutions specializing in heavy equipment loans. They can often provide competitive rates and flexible terms tailored to your business needs.

- Consider a Professional Appraisal: For high-value used trucks, an independent appraisal can provide an unbiased assessment of its condition and market value.

Challenges and Solutions in Ready Mix Concrete Truck Ownership

Owning and operating ready mix concrete trucks comes with its own set of challenges, but proactive planning can mitigate most of them.

- Challenge: High Initial Investment:

- Solution: Explore financing options like equipment loans, leases, or purchasing well-maintained used trucks. Consider the long-term ROI rather than just the upfront cost.

- Challenge: Intensive Maintenance and Potential Downtime:

- Solution: Implement a rigorous preventative maintenance schedule. Regularly check fluid levels, tires, brakes, and critical components. Train your operators on daily inspection routines. Establish relationships with reliable mechanics specializing in heavy trucks and mixers. Keep a stock of essential spare parts for quick fixes.

- Challenge: Skilled Operator Shortage and Safety Concerns:

- Solution: Invest in comprehensive training programs for your drivers, focusing on safe operation, concrete handling, and routine maintenance checks. Emphasize safety protocols for loading, transit, and discharge. Ensure operators hold the necessary commercial driver’s licenses (CDLs).

- Challenge: Environmental Regulations and Washout Procedures:

- Solution: Adhere strictly to local environmental regulations regarding concrete washout. Establish designated washout areas at your yard that prevent contaminated water from entering storm drains or local water bodies. Explore technologies like concrete reclaimers that recover aggregates and reduce waste.

- Challenge: Fuel Costs and Operational Efficiency:

- Solution: Implement route optimization software to minimize travel time and fuel consumption. Train drivers on fuel-efficient driving techniques. Regularly maintain engines to ensure optimal performance. Consider newer models with improved fuel economy or alternative fuel options if available and viable.

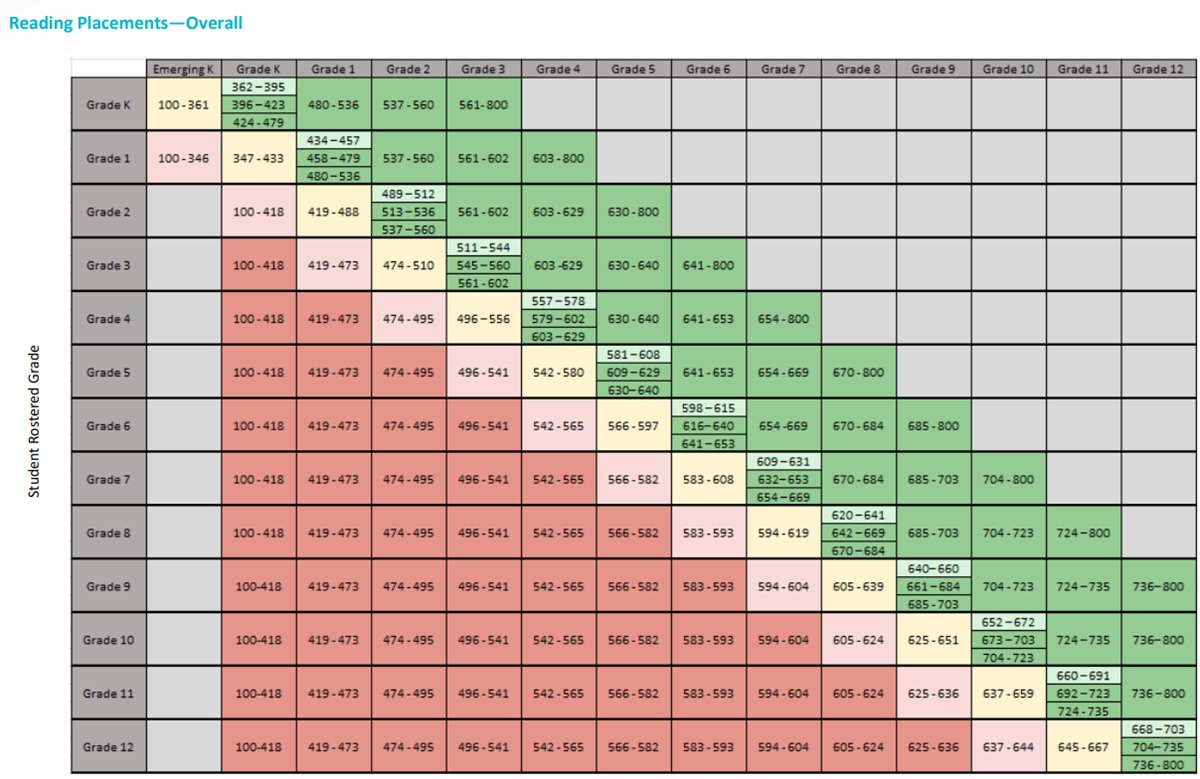

Price Table: Ready Mix Concrete Trucks For Sale (Estimates)

Please note that these are approximate price ranges and can vary significantly based on brand, model year, condition, features, mileage/hours, and market demand. Always request specific quotes.

| Category | Capacity (Cubic Yards) | Approximate Price Range (USD) | Key Features/Considerations |

|---|---|---|---|

| New Trucks | 6-8 YD | $180,000 – $250,000+ | Latest emissions standards, warranty, custom options, high reliability. |

| 9-12 YD | $220,000 – $350,000+ | Higher capacity, advanced features, often custom-built. | |

| Used Trucks | 6-8 YD (5-10 years old) | $60,000 – $120,000 | Good balance of cost and performance, check maintenance records. |

| 9-12 YD (5-10 years old) | $80,000 – $150,000 | Higher capacity for larger projects, inspect drum and chassis thoroughly. | |

| 6-12 YD (10+ years old) | $20,000 – $70,000 | Most budget-friendly, likely requires more immediate maintenance, extensive inspection crucial. | |

| Specialty | Volumetric Mixers | $100,000 – $300,000+ | Concrete mixed on-site, precise volume, different operating model. |

Frequently Asked Questions (FAQ) About Ready Mix Concrete Trucks

Q1: What is the average lifespan of a ready mix concrete truck?

A1: With proper maintenance, a ready mix concrete truck can last 10-20 years or more. The chassis often outlasts the mixer drum, which may require replacement or significant repair around the 7-10 year mark depending on usage.

Q2: How much does a new concrete truck cost?

A2: New ready mix concrete trucks typically range from $180,000 to over $350,000, depending on capacity, chassis manufacturer, mixer brand, and specific features.

Q3: What is the difference between a transit mixer and a volumetric mixer?

A3: A transit mixer (or ready mix truck) carries pre-mixed concrete from a batch plant. A volumetric mixer carries raw materials (cement, aggregates, water) separately and mixes the concrete on-site, allowing for precise volume control and fresh concrete as needed.

Q4: What essential maintenance is required for a concrete truck?

A4: Regular maintenance includes daily washdowns of the drum and chutes, greasing of moving parts, checking fluid levels (engine oil, transmission, hydraulics), tire pressure checks, brake inspections, and scheduled engine/transmission servicing. Preventing concrete buildup inside and outside the drum is critical.

Q5: Can I operate a concrete truck without a special license?

A5: In most regions, operating a ready mix concrete truck requires a Commercial Driver’s License (CDL) due to its size, weight, and classification as a commercial vehicle. Specific endorsements (like air brakes) may also be necessary.

Q6: How do I determine the right drum size for my needs?

A6: Assess the typical concrete volume required for your projects. If you frequently handle large pours (e.g., commercial foundations), a 10 or 12 cubic yard truck might be efficient. For smaller, more frequent jobs or restricted access sites, a 6 or 8 cubic yard truck could be more suitable.

Q7: What are common red flags when buying a used concrete truck?

A7: Red flags include excessive rust on the chassis or frame, significant concrete buildup inside the drum (indicating poor washout practices), leaks from hydraulic lines or engine, warning lights on the dashboard, inconsistent drum rotation, or a lack of maintenance records.

Conclusion

The decision to purchase ready mix concrete trucks for sale is a strategic move that can significantly bolster your operational capabilities and bottom line in the construction industry. By understanding the different types available, diligently considering key factors like budget and project needs, and employing smart acquisition tips, you can navigate the market with confidence. While challenges such as maintenance and regulatory compliance exist, proactive planning and a commitment to safety and efficiency will ensure your investment serves you reliably for years to come. With the right ready mix concrete truck, you’re not just buying a machine; you’re investing in the very foundation of your future success.