Aluminum Toolbox For Pickup Trucks pickup.truckstrend.com

Pickup trucks are the quintessential workhorses of the automotive world, relied upon by contractors, tradespeople, outdoor enthusiasts, and DIYers alike for their unparalleled utility. However, the open bed, while versatile, often presents a challenge: how to securely store and organize tools, equipment, and personal gear, protecting them from theft, weather, and the rigors of the road. Enter the aluminum toolbox for pickup trucks – an indispensable accessory that transforms an open bed into a secure, organized, and highly functional storage solution.

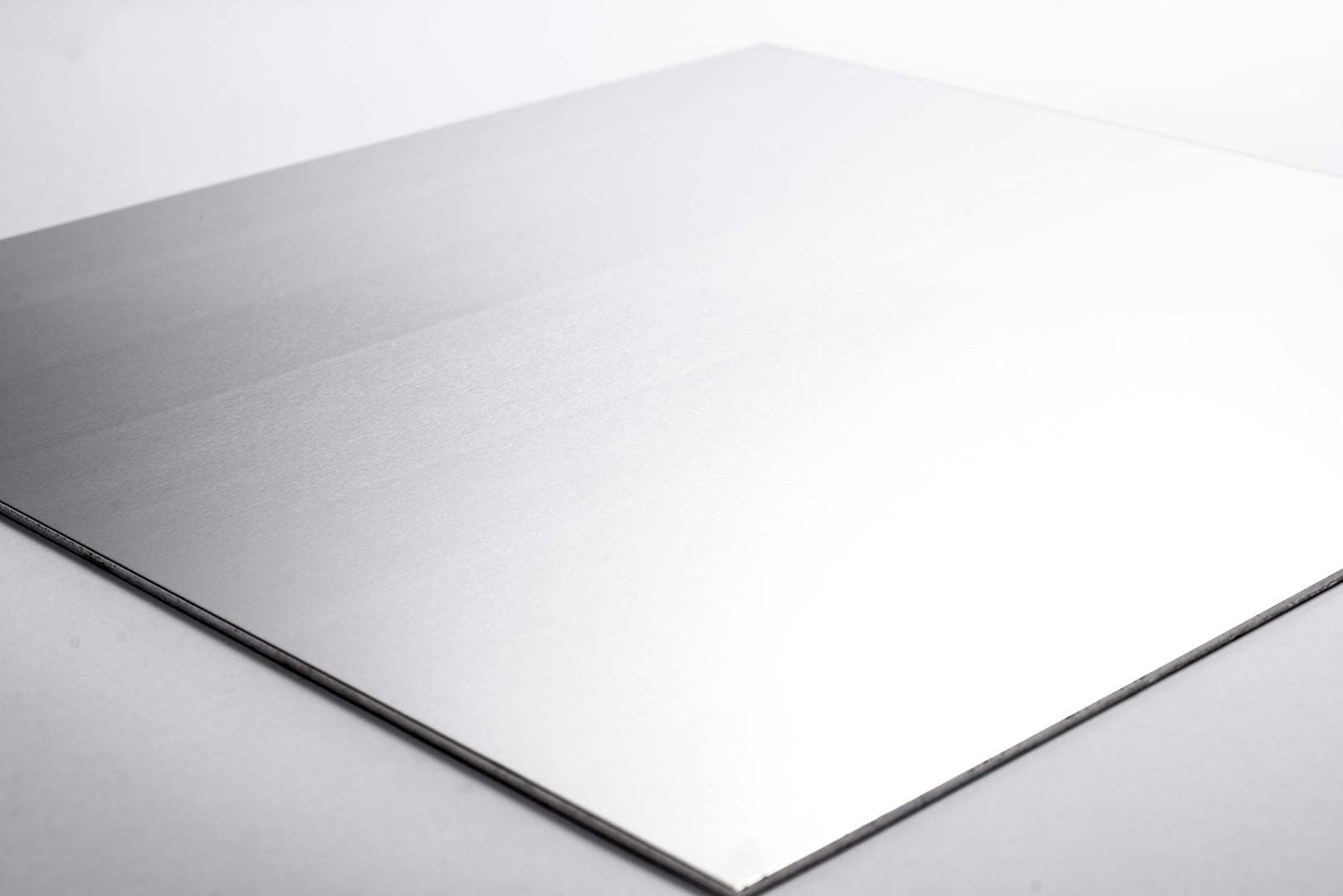

An aluminum toolbox is specifically designed to fit into the bed of a pickup truck, providing a robust, weather-resistant, and lockable compartment for a wide array of items. Crafted from lightweight yet incredibly durable aluminum, these toolboxes are engineered to withstand harsh conditions, offering peace of mind that valuable contents are protected. More than just a simple box, they are a critical investment for anyone who depends on their truck for work or adventure, ensuring that essential tools are always on hand, organized, and safe.

Aluminum Toolbox For Pickup Trucks

Why Choose an Aluminum Toolbox? Benefits Explored

The popularity of aluminum toolboxes isn’t accidental; it’s a direct result of the numerous practical benefits they offer over other materials or storage methods.

- Unrivaled Durability and Longevity: Aluminum is naturally resistant to rust and corrosion, unlike steel, which can quickly degrade when exposed to moisture and road salts. This inherent resistance means an aluminum toolbox can withstand extreme weather conditions – from torrential rain and snow to blistering sun – without compromising its structural integrity or appearance. Diamond plate aluminum, a common finish, further enhances durability by providing a textured surface that resists scratches and minor dents.

- Lightweight Advantage: One of aluminum’s most significant advantages is its high strength-to-weight ratio. An aluminum toolbox is considerably lighter than its steel counterpart, which translates into several benefits. It minimizes the impact on your truck’s fuel efficiency, reduces the overall payload weight, and makes installation and removal much easier. This lightweight nature also means less strain on your truck’s suspension and chassis.

- Superior Security: Protecting valuable tools and equipment from theft is paramount. Aluminum toolboxes are designed with robust locking mechanisms, often featuring heavy-duty paddle latches, push-button locks, or sophisticated cam locks. Combined with sturdy construction, these features create a formidable barrier against unauthorized access, offering peace of mind whether your truck is parked on a job site or in your driveway.

- Optimal Organization: Beyond mere storage, aluminum toolboxes excel at organization. Many models come equipped with internal trays, dividers, and compartments, allowing users to neatly arrange tools, small parts, and accessories. This level of organization saves valuable time on the job, as tools are easily accessible and not jumbled together, preventing damage and frustration.

- Versatility for Every Need: Whether you’re a professional contractor needing to secure power tools, a landscaper storing gardening equipment, an adventurer stowing camping gear, or a DIY enthusiast keeping household tools, there’s an aluminum toolbox configuration to suit your specific requirements. Their adaptability makes them an essential accessory across diverse professions and hobbies.

- Aesthetic Appeal: Beyond functionality, aluminum toolboxes often boast a sleek, professional appearance. The polished diamond plate or smooth finishes add a rugged yet refined look to any pickup truck, complementing its utilitarian aesthetic.

Types of Aluminum Toolboxes for Pickup Trucks

Aluminum toolboxes come in various designs, each optimized for different storage needs and truck bed configurations. Understanding these types is crucial for selecting the best fit.

- Crossover/Cross-Bed Toolboxes:

- Description: These are the most common type, designed to sit across the width of the truck bed, resting on the bed rails behind the cab. They typically feature one or two lids that open upwards.

- Pros: Excellent storage capacity, easy access from either side of the truck, keeps the majority of the truck bed floor open underneath.

- Cons: Takes up some bed length, potentially limiting the ability to carry very long items.

- Side-Mount Toolboxes:

- Description: These toolboxes are mounted along the side rails of the truck bed, running parallel to the cab. They often have a single lid that opens towards the center of the bed.

- Pros: Keeps the entire bed floor clear for hauling large items, good for organizing smaller tools and equipment along the sides.

- Cons: Generally offer less overall capacity than crossover boxes, access can be slightly more challenging depending on truck height.

- Wheel Well Toolboxes:

- Description: Designed to fit snugly over the rear wheel wells in the truck bed, utilizing space that is often otherwise wasted.

- Pros: Maximizes unused space, keeps the main bed area clear, provides convenient storage for frequently used items.

- Cons: Limited in size and shape due to the wheel well contour, typically smaller capacity.

- Chest Toolboxes:

- Description: These are rectangular boxes designed to sit directly on the floor of the truck bed, either against the cab or anywhere else in the bed. They usually have a single lid that opens upwards.

- Pros: Very high storage capacity, extremely secure as they are low-profile and often bolted down, can be moved if needed.

- Cons: Takes up significant bed floor space, requires reaching into the bed for access, can obstruct visibility if placed improperly.

- Underbody Toolboxes:

- Description: While less common for standard pickup beds, these boxes are mounted underneath the truck chassis or behind the rear wheels, often seen on flatbed trucks or custom setups.

- Pros: Frees up bed space entirely, provides discreet storage.

- Cons: Requires specific mounting hardware and vehicle clearance, less convenient access.

Key Features to Look For When Buying

Choosing the right aluminum toolbox involves more than just picking a type. Several key features contribute to its functionality, durability, and security.

- Material Gauge: The thickness of the aluminum sheet metal, measured in gauge (lower number means thicker material). Thicker gauge aluminum (e.g., 0.063" or 0.080") indicates a more robust and dent-resistant toolbox, crucial for longevity and protecting contents.

- Locking Mechanism: Inspect the quality and type of lock. Paddle latches are common and secure. Push-button locks offer convenience, while cam locks provide robust security. Ensure the lock is weather-sealed and uses a high-quality cylinder to deter tampering.

- Weather Sealing: A high-quality rubber or foam gasket around the lid’s perimeter is essential to keep water, dust, and debris out. Look for continuous, well-fitted seals that compress tightly when the lid is closed.

- Lid Design and Struts: Check if the lid opens smoothly and stays open without manual support. Gas struts (shock absorbers) are a premium feature that makes opening and closing effortless and prevents accidental slamming. Some toolboxes offer single or dual lids, impacting access.

- Mounting System: How the toolbox attaches to your truck bed is critical for security and stability. Common methods include J-hooks that clamp onto the bed rails (no drilling required) or bolt-through options for maximum security (requires drilling). Ensure the mounting hardware is sturdy and corrosion-resistant.

- Internal Organization: Evaluate the internal layout. Does it include removable trays for small items, adjustable dividers, or built-in compartments? These features significantly enhance organization and accessibility.

- Dimensions and Capacity: Accurately measure your truck bed (width, length, depth) and consider any existing bed liners or accessories. Compare these measurements with the toolbox dimensions to ensure a perfect fit and adequate storage capacity for your needs.

- Finish: Common finishes include diamond plate (textured, scratch-resistant, rugged look) and smooth aluminum (sleek, professional look, easier to clean). Some toolboxes are also powder-coated for added protection and color.

Installation and Maintenance Guide

Proper installation and routine maintenance are crucial for maximizing the lifespan and performance of your aluminum toolbox.

Installation:

- Safety First: Always wear appropriate personal protective equipment, including gloves and eye protection.

- Positioning: Carefully place the toolbox in your desired location in the truck bed. For crossover boxes, center it behind the cab, ensuring clearance from the cab window and bed rails. For side-mounts, align them along the rail.

- Secure the Toolbox:

- J-Hook Method (No-Drill): Most common for crossover boxes. Position the J-hooks around the bed rail and secure them with bolts from inside the toolbox. Tighten evenly until snug, but do not overtighten to avoid damaging the bed rails.

- Bolt-Through Method (Drill Required): For maximum security. Mark and drill holes through the toolbox floor and the truck bed. Use large washers and lock nuts to secure the bolts from underneath the bed. Apply sealant around the drilled holes to prevent water intrusion.

- Check for Stability: Once installed, firmly shake the toolbox to ensure it’s securely mounted and doesn’t wobble or shift.

Maintenance:

- Regular Cleaning: Periodically clean the exterior and interior with mild soap and water. Avoid abrasive cleaners or harsh chemicals that can damage the aluminum finish. Rinse thoroughly and dry to prevent water spots.

- Lubricate Moving Parts: Apply a silicone-based lubricant to hinges, gas struts, and lock mechanisms every few months to ensure smooth operation and prevent corrosion.

- Inspect Seals: Routinely check the rubber or foam weather seals around the lid for cracks, tears, or compression. Worn seals can lead to water leakage. Replace them if necessary.

- Check Mounting Hardware: Periodically inspect the J-hooks or bolts for tightness. Vibrations from driving can sometimes loosen them over time. Retighten as needed.

- Drainage: Ensure any drain holes (if present) are clear of debris to prevent water accumulation inside the box.

Challenges and Solutions

While highly beneficial, aluminum toolboxes can present minor challenges, which can often be easily overcome.

- Challenge: Cost: Aluminum toolboxes can be a significant investment compared to plastic or steel alternatives.

- Solution: View it as a long-term investment in security, durability, and organization. Compare prices from different reputable brands and models to find one that fits your budget while meeting your needs. The longevity of aluminum often outweighs the initial higher cost.

- Challenge: Takes Up Bed Space: Crossover and chest toolboxes consume valuable bed length or floor space.

- Solution: Carefully assess your typical hauling needs. If you frequently carry long items, consider side-mount or wheel well toolboxes, which keep the main bed floor clear. If maximum capacity is needed, a chest box might be the best compromise, accepting the trade-off in bed space.

- Challenge: Potential for Dents/Scratches: While durable, aluminum can still dent or scratch under heavy impact or abrasive contact.

- Solution: Opt for a thicker gauge aluminum (e.g., 0.080") for enhanced dent resistance. Diamond plate finishes are more resistant to minor scratches than smooth finishes. Consider lining the interior with rubber mats to protect both the toolbox and its contents.

- Challenge: Rattling Noises: An improperly installed or empty toolbox can sometimes rattle while driving.

- Solution: Ensure the toolbox is securely mounted and all hardware is tightened. Place rubber mats or foam padding inside the box to prevent tools from shifting and rattling. Check that the lid closes tightly and the weather seal provides adequate cushioning.

Practical Advice & Actionable Insights

Making the right choice for an aluminum toolbox can significantly enhance your truck’s utility.

- Measure Meticulously: Before even looking at models, precisely measure your truck bed’s width (between rails and at the floor), length, and height. Account for any bed liners, tonneau covers, or other accessories that might affect fitment.

- Define Your Primary Use: Are you storing heavy power tools, delicate surveying equipment, camping gear, or roadside emergency kits? Your primary use case will dictate the required capacity, internal organization, and desired level of security.

- Research Brands and Reviews: Don’t just pick the first one you see. Look into reputable brands known for quality and durability (e.g., Weather Guard, Dee Zee, UWS, Lund). Read customer reviews to gauge real-world performance and common issues.

- Prioritize Security Features: If you’re storing valuable items, do not compromise on the locking mechanism and overall construction. Look for robust latches, high-quality lock cylinders, and a secure mounting system.

- Consider Future Needs: While you might only need a small box now, think about potential future uses. Investing in a slightly larger or more versatile toolbox initially might save you money and hassle down the road.

- DIY Installation vs. Professional: Most aluminum toolboxes are designed for DIY installation with basic tools. However, if you’re uncomfortable drilling into your truck bed or want absolute peace of mind, consider professional installation.

Price Table: Aluminum Toolboxes for Pickup Trucks (Estimated Ranges)

| Toolbox Type | Approximate Capacity (Cubic Feet) | Typical Price Range (USD) | Key Features & Considerations |

|---|---|---|---|

| Crossover/Cross-Bed | |||

| Compact (60-65") | 5 – 8 cu ft | $300 – $600 | Fits smaller trucks or those needing less capacity. Single lid common. |

| Standard (70-74") | 8 – 12 cu ft | $400 – $800 | Most common size. Often dual lids, gas struts, internal trays. |

| Large/Full-Size (80"+) | 12 – 18+ cu ft | $600 – $1200+ | For full-size trucks. Maximum storage, heavy-duty construction. |

| Side-Mount | 3 – 6 cu ft | $250 – $550 | Keeps bed floor clear. Good for frequently accessed smaller tools. |

| Wheel Well | 1.5 – 3 cu ft | $200 – $450 | Utilizes unused space. Best for specific, smaller items. |

| Chest | 10 – 25+ cu ft | $450 – $1000+ | High capacity, very secure. Sits on bed floor, can be portable. |

| Underbody | 2 – 10 cu ft (per box) | $300 – $700+ (per box) | Requires specific mounting. Excellent for maximizing bed space. |

Note: Prices are estimates and can vary significantly based on brand, material gauge, features (e.g., gas struts, premium locks, powder coating), retailer, and current market conditions.

Frequently Asked Questions (FAQ)

Q1: Are aluminum toolboxes truly rust-proof?

A1: Aluminum is highly resistant to rust and corrosion, unlike steel. While it won’t rust in the traditional sense, it can oxidize (form a white powdery film) under certain conditions, which is generally harmless and can be cleaned. For practical purposes, they are considered rust-proof in typical outdoor environments.

Q2: How much weight can an aluminum toolbox hold?

A2: The weight capacity varies significantly depending on the toolbox’s gauge (thickness of the aluminum), design, and mounting method. A well-built, heavy-gauge aluminum toolbox can typically hold hundreds of pounds. Always check the manufacturer’s specifications for the exact weight limit of a particular model.

Q3: Will an aluminum toolbox affect my truck’s fuel economy?

A3: Due to their lightweight nature, aluminum toolboxes have a minimal impact on fuel economy compared to heavier steel alternatives. Any impact would be negligible for most users, primarily due to the added weight and slight aerodynamic drag.

Q4: Can I install an aluminum toolbox myself, or do I need professional help?

A4: Most aluminum toolboxes are designed for DIY installation using basic hand tools (wrenches, drills for bolt-through methods). Manufacturers provide detailed instructions. However, if you’re uncomfortable with the process or prefer not to drill into your truck bed, professional installation services are available.

Q5: What’s the difference between smooth and diamond plate aluminum?

A5: The primary difference is aesthetic and practical. Diamond plate aluminum has a raised, textured pattern that provides a more rugged look and offers increased grip and resistance to minor scratches and scuffs. Smooth aluminum offers a sleeker, more polished appearance and is generally easier to clean, though it may show scratches more readily. Both offer similar strength characteristics if the gauge is the same.

Q6: Do aluminum toolboxes come with internal dividers or trays?

A6: Many higher-end or standard models include removable plastic or aluminum trays for organizing smaller items and sometimes adjustable dividers. Some basic models may not, but internal organization accessories are often sold separately by manufacturers or third parties.

Conclusion

The aluminum toolbox for pickup trucks stands out as an essential and highly beneficial accessory for any truck owner. Its unparalleled combination of durability, lightweight design, superior security, and efficient organization capabilities makes it an indispensable asset. Whether you’re a professional needing reliable tool storage, a weekend warrior securing your adventure gear, or a home improvement enthusiast keeping your essentials safe, an aluminum toolbox transforms your truck’s bed into a highly functional and protected space.

Investing in a quality aluminum toolbox is not merely buying a storage container; it’s investing in productivity, security, and peace of mind. By carefully considering the type, features, and proper maintenance, you can ensure that your aluminum toolbox serves you faithfully for years to come, keeping your valuable equipment safe, organized, and ready for whatever the road – or the job – throws your way.