Fiberglass Race Truck Bodies: The Lightweight Edge in Motorsports pickup.truckstrend.com

In the high-octane world of motorsports, where every ounce and every fraction of a second counts, the choice of materials for a race vehicle’s body is paramount. Among the various options, Fiberglass Race Truck Bodies stand out as a cornerstone for builders and racers seeking a potent combination of performance, durability, and cost-effectiveness. These lightweight, custom-molded shells are far more than just aesthetic coverings; they are critical components engineered to reduce weight, optimize aerodynamics, and withstand the punishing demands of competitive racing, from desert rallies to short track oval events.

This comprehensive guide delves into the intricate world of fiberglass race truck bodies, exploring their composition, myriad benefits, important considerations for selection, practical installation and maintenance tips, and common challenges. Whether you’re a seasoned racer, a dedicated fabricator, or an enthusiast curious about the engineering behind the speed, understanding fiberglass is key to unlocking a competitive edge.

Fiberglass Race Truck Bodies: The Lightweight Edge in Motorsports

The Science Behind the Speed: Why Fiberglass?

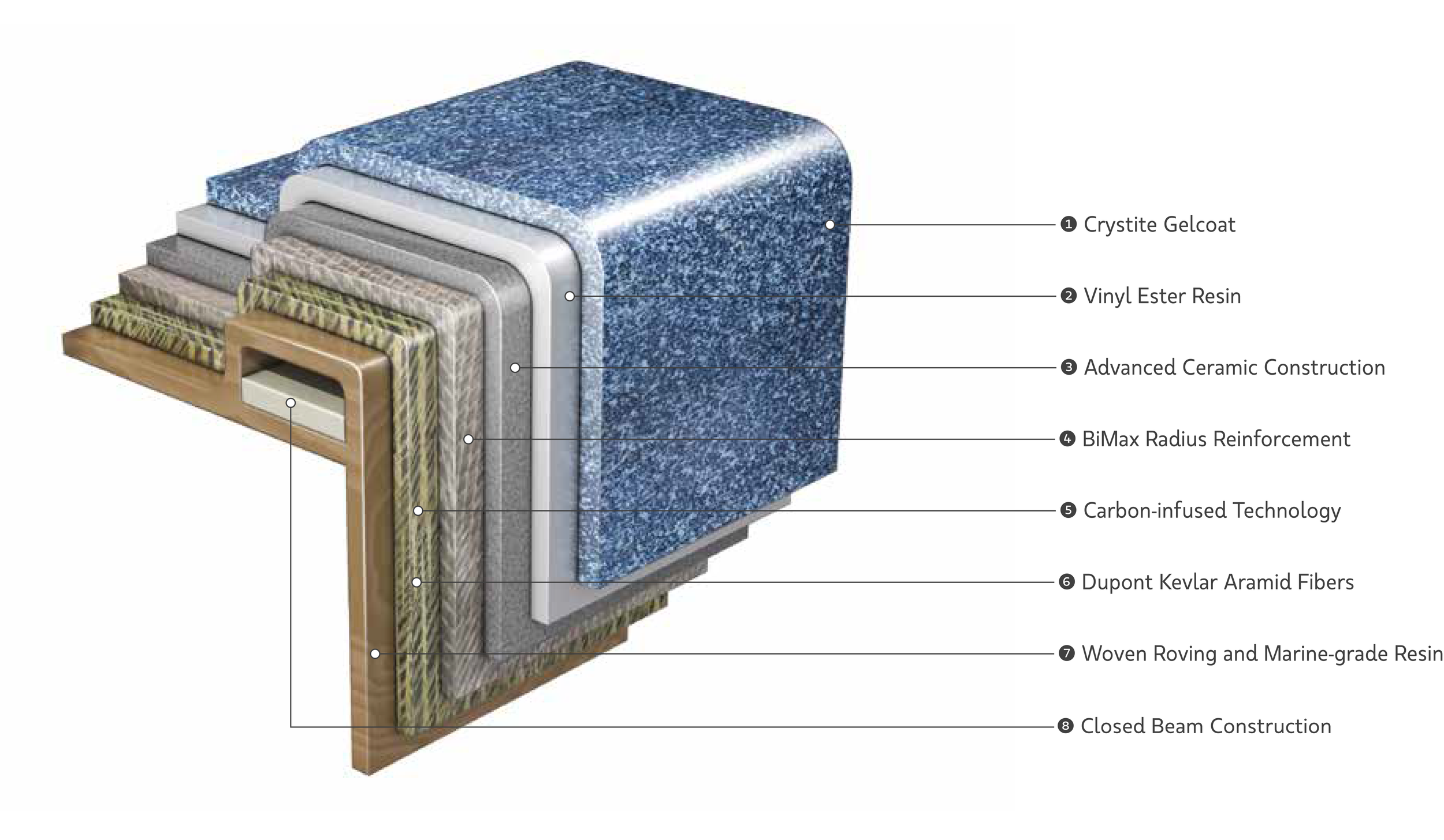

At its core, fiberglass is a composite material made from fine fibers of glass woven into a fabric, which is then saturated with a polymer resin (typically polyester or vinyl ester) and allowed to cure and harden. This process creates a remarkably strong yet incredibly lightweight material.

The allure of Fiberglass Race Truck Bodies stems from several inherent properties of this composite:

- Exceptional Strength-to-Weight Ratio: Glass fibers provide immense tensile strength, while the resin binds them into a rigid structure. This results in a material that is significantly lighter than steel or even aluminum, yet robust enough to handle the stresses of racing.

- Rigidity and Formability: Fiberglass can be molded into complex, aerodynamic shapes that would be difficult or prohibitively expensive to achieve with metal fabrication. Once cured, it maintains its shape, contributing to structural integrity.

- Impact Resistance: While not indestructible, fiberglass can absorb and distribute impact forces, often deforming or cracking rather than shattering, which can be advantageous in minor collisions. More importantly, unlike steel that dents easily, fiberglass often springs back or can be repaired more readily.

- Corrosion Resistance: Unlike metals, fiberglass does not rust or corrode, making it ideal for various racing environments, including those with moisture or abrasive elements like dirt and sand.

Unpacking the Benefits of Fiberglass Race Truck Bodies

The decision to equip a race truck with fiberglass body panels is driven by a multitude of performance advantages:

- Drastic Weight Reduction: This is arguably the most significant benefit. Removing hundreds of pounds from a race truck directly translates to improved acceleration, higher top speeds, better braking performance, and more agile handling. A lighter vehicle also places less stress on the suspension, drivetrain, and tires, potentially extending component life.

- Aerodynamic Efficiency: Fiberglass allows for the creation of smooth, seamless surfaces and intricate contours that minimize drag and, where applicable, generate downforce. Custom front clips, flared fenders, and bedsides can be designed to channel airflow efficiently around and over the truck, enhancing stability and speed.

- Durability and Repairability: While not as ductile as steel, fiberglass exhibits excellent resistance to minor impacts and vibrations common in racing. Crucially, if damage does occur, fiberglass is highly repairable. Cracks, holes, and even larger sections can often be patched and reinforced, extending the lifespan of the body panels and reducing replacement costs.

- Cost-Effectiveness: Compared to bespoke metal fabrication for custom race bodies, fiberglass molding is often a more economical solution, especially for manufacturers producing multiple units. The initial investment is typically lower, and the ease of repair further contributes to long-term savings.

- Customization and Aesthetics: Fiberglass offers unparalleled design freedom. Teams can choose from a vast array of pre-designed body kits or opt for custom molds to create a unique look that also provides a performance advantage. The smooth gel coat finish provides an excellent base for paint and graphics, allowing teams to showcase sponsors and brand identity.

Types and Construction Methods

Fiberglass Race Truck Bodies are available in various forms and produced using different methods, each with its own characteristics:

- Full Body Kits: These comprehensive packages typically include a one-piece front clip (nose, fenders, cowl), separate doors, and rear bedsides. They are designed to transform the appearance and performance of a stock truck chassis into a purpose-built race machine.

- Individual Panels: For targeted upgrades, repairs, or specific class regulations, individual fiberglass components like standalone fenders, hoods, or doors are widely available.

- Hand Lay-up: This is the most common and traditional method for producing fiberglass race truck bodies, especially for custom or lower-volume production. Layers of fiberglass mat or woven fabric are manually placed into a mold and saturated with resin using rollers and brushes. While labor-intensive, it allows for flexibility in design and material thickness.

- Vacuum Infusion/Bagging: A more advanced technique where dry fiberglass fabrics are placed in a mold, a vacuum bag is sealed over them, and resin is then drawn into the mold by vacuum pressure. This method results in a part with a higher fiber-to-resin ratio, fewer air bubbles, and superior strength and lighter weight, albeit at a higher cost.

Important Considerations for Selecting Fiberglass Race Truck Bodies

Choosing the right Fiberglass Race Truck Bodies requires careful thought to ensure optimal performance, safety, and compliance:

- Race Series Regulations: Always, always check the rulebook for your specific racing series. There may be limitations on dimensions, materials, or even the type of body panels allowed. Compliance is non-negotiable.

- Fitment and Compatibility: Ensure the body kit or individual panels are specifically designed for your truck’s chassis or the dimensions of your custom race frame. Poor fitment leads to wasted time, structural compromises, and an unprofessional appearance.

- Quality of Construction: Inspect the fiberglass parts before purchase. Look for a smooth, consistent gel coat (the outer protective layer), uniform thickness, and an absence of excessive air bubbles or voids. Reputable manufacturers use higher-quality resins and more meticulous lay-up processes.

- Mounting and Fastening: Consider how the body panels will attach to the chassis. Proper mounting points, reinforced areas, and compatible fasteners (e.g., Dzus fasteners for quick removal, bolts for more permanent fixtures) are crucial for safety and structural rigidity, especially at high speeds or over rough terrain.

- Aerodynamic Design: For certain racing disciplines, the aerodynamic profile of the body can be a significant performance factor. Evaluate how the chosen body shape contributes to airflow, drag reduction, and stability.

- Budget vs. Performance: While fiberglass is cost-effective, prices vary based on quality, manufacturer, and complexity. Balance your budget with the performance gains and durability you expect.

Installation and Maintenance Tips

Proper installation and ongoing maintenance are key to maximizing the lifespan and performance of Fiberglass Race Truck Bodies:

- Pre-Installation Prep: Always test fit all panels before painting or final installation. Trimming and sanding may be required for a perfect fit. Mark all mounting points accurately.

- Secure Mounting: Use appropriate hardware and reinforce mounting areas on both the body and the chassis. Over-drilling holes slightly can prevent stress cracks from vibration. Ensure panels are securely fastened to prevent them from becoming airborne at speed.

- Painting: For best results, clean and sand the gel coat thoroughly. Apply a flexible primer designed for plastics or composites, followed by high-quality automotive paint that can withstand the rigors of racing.

- Regular Cleaning: Wash fiberglass panels with mild soap and water. Avoid harsh abrasives or solvents that can damage the gel coat or paint.

- Prompt Repair: Address any cracks, chips, or damage immediately. Small imperfections can propagate into larger problems. Keep a basic fiberglass repair kit (resin, hardener, mat, sanding tools) on hand for quick fixes.

- Reinforcement: Identify high-stress areas (e.g., around mounting points, edges) and consider adding extra layers of fiberglass mat or carbon fiber reinforcement during initial installation or repair for added durability.

Challenges and Solutions

While highly advantageous, Fiberglass Race Truck Bodies do present a few challenges:

- Brittleness/Cracking: Compared to metal, fiberglass can be more prone to cracking or shattering under extreme impact.

- Solution: Reinforce high-stress areas, use a slightly more flexible resin system (like vinyl ester), and ensure proper mounting to distribute loads.

- UV Degradation: Prolonged exposure to sunlight can degrade the resin, leading to fading, chalking, and reduced strength over time.

- Solution: Use a UV-resistant gel coat, apply high-quality UV-protective paint, and store the truck indoors when not in use.

- Flex/Warping: Thin or poorly supported panels can flex or warp, especially under aerodynamic load or heat.

- Solution: Choose thicker gauge fiberglass in critical areas, add internal bracing, or opt for vacuum-infused parts for superior rigidity.

- Initial Cost: While cost-effective long-term, the initial outlay for a full fiberglass body kit can be significant.

- Solution: Consider purchasing individual panels over time, look for used parts, or prioritize the most impactful components (e.g., front clip for aerodynamics).

Price Table: Estimated Costs for Fiberglass Race Truck Bodies

Please note that these are estimated price ranges and can vary significantly based on manufacturer, specific truck model, quality of materials, complexity of design, and current market conditions. Custom work will always incur higher costs.

| Component / Service | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Full Race Truck Body Kit | Complete set: Front clip, fenders, doors, bedsides, cowl, etc. | $2,500 – $8,000+ | Varies by truck model, manufacturer reputation, and quality of lay-up. |

| Front Clip (One-piece) | Nose, grille opening, headlight buckets, integrated fenders. | $700 – $2,500 | Common for various racing series, significant aerodynamic impact. |

| Fenders (Pair) | Front or Rear Fenders (often oversized for tire clearance). | $300 – $800 | Essential for tire coverage and aerodynamics. |

| Doors (Pair) | Outer skin only, or partial inner structure (non-functional for weight). | $400 – $1,200 | Lighter than factory doors, typically bolted or Dzus-fastened. |

| Bedsides (Pair) | Rear quarter panels / bed sides (often flared or extended). | $500 – $1,500 | Crucial for rear aerodynamics and tire clearance. |

| Cowl / Dash Panel | Interior dash/windshield surround for lightweight interior. | $150 – $400 | Replaces heavier stock dashboard components. |

| Custom Mold Fabrication Fee | For completely unique designs, requiring a new mold to be created. | $5,000 – $20,000+ | High initial cost, but allows for exclusive designs and multiple copies. |

| Basic Fiberglass Repair Kit | Resin, hardener, fiberglass mat/cloth, mixing cups, brushes, sandpaper. | $50 – $150 | Essential for DIY minor repairs, a must-have for any race team. |

| Professional Repair Service | Hourly rate or per-damage estimate for significant repairs. | $75 – $150/hour | Depends on the extent of damage, labor rates, and material costs. |

Frequently Asked Questions (FAQ) about Fiberglass Race Truck Bodies

Q: Are fiberglass bodies durable enough for racing?

A: Absolutely. When properly constructed from quality materials and correctly installed, fiberglass race truck bodies are highly durable. They are designed to withstand the stresses of racing, offering good impact resistance and being remarkably repairable, which is a major advantage over traditional sheet metal.

Q: How much weight can I expect to save with fiberglass components?

A: The weight savings can be substantial, often ranging from hundreds of pounds compared to a stock steel body. The exact amount depends on the original vehicle’s components being replaced and the specific fiberglass parts installed. This significant reduction directly translates to performance gains.

Q: Is fiberglass difficult to repair if damaged during a race?

A: Minor repairs to fiberglass, such as small cracks or holes, are relatively straightforward for a DIY enthusiast with basic tools and a fiberglass repair kit. More extensive damage might require professional repair services, but generally, fiberglass is considered easier and less costly to repair than heavily damaged metal panels.

Q: Do I need a full body kit, or can I just replace individual panels?

A: It depends on your budget, specific needs, and the racing class rules. Many racers start by replacing key components like the front clip or fenders for immediate weight savings and aerodynamic benefits. A full kit offers the most comprehensive transformation and weight reduction.

Q: Are fiberglass race truck bodies street legal?

A: Generally, no. Fiberglass Race Truck Bodies are designed purely for competition and lack the structural integrity, crash safety features (like crumple zones), and sometimes the specific mounting points for lighting required for street legality. They are intended for off-road or track-only use.

Q: What’s the difference between "hand lay-up" and "vacuum infusion" in fiberglass construction?

A: Hand lay-up is a manual process where resin is applied by hand. Vacuum infusion involves placing dry fabric in a mold, sealing it with a vacuum bag, and then using vacuum pressure to pull resin through the fabric. Vacuum infusion results in a stronger, lighter, and more consistent part with fewer air bubbles, but it’s a more complex and expensive process.

Q: How do I properly paint a fiberglass body for a race truck?

A: Proper preparation is key. The fiberglass surface (gel coat) should be thoroughly cleaned, lightly sanded for adhesion, and then primed with a flexible primer designed for composites. Finally, apply a high-quality automotive paint that can withstand the demanding conditions of racing and offers UV protection.

Conclusion

Fiberglass Race Truck Bodies are an indispensable asset in modern motorsports, offering a powerful blend of lightweight performance, aerodynamic flexibility, and impressive durability. They enable racers to push the boundaries of speed and handling by drastically reducing vehicle weight and allowing for optimized airflow. While requiring careful selection, proper installation, and diligent maintenance, the advantages they provide—from enhanced acceleration and braking to improved handling and reduced long-term costs—make them a strategic choice for any serious competitor.

As racing continues to evolve, fiberglass remains at the forefront, continually refined and innovated upon, ensuring that race trucks are not just powerful machines, but highly efficient, purpose-built instruments of speed. For those building or campaigning a race truck, understanding and leveraging the benefits of fiberglass is not just an option, but a vital component in the relentless pursuit of victory.