Load Locks For Pickup Trucks: Securing Your Cargo Safely and Efficiently pickup.truckstrend.com

Every pickup truck owner knows the immense utility and versatility their vehicle offers. From hauling construction materials and camping gear to moving furniture or transporting recreational vehicles, a truck bed is a workhorse. However, this utility comes with a critical responsibility: ensuring that whatever you’re carrying stays securely in place. This is where Load Locks For Pickup Trucks become indispensable. More than just a simple accessory, load locks are a comprehensive system of devices designed to prevent cargo from shifting, sliding, or bouncing during transit, safeguarding your cargo, your truck, and everyone else on the road.

Without proper load locks, even a seemingly stable item can become a dangerous projectile under sudden braking, acceleration, or turns. This comprehensive guide will delve into the world of load locks, exploring their types, benefits, proper usage, and crucial considerations to help you become a master of cargo security.

Load Locks For Pickup Trucks: Securing Your Cargo Safely and Efficiently

Understanding Load Locks: More Than Just Straps

While tie-down straps are a vital component of cargo security, the term "Load Locks For Pickup Trucks" encompasses a broader array of tools focused on internal bed management and stabilization. These devices work by creating barriers, compartments, or pressure points within the truck bed to hold items firmly in place, complementing the role of tie-downs that anchor items to the bed. The goal is to eliminate any potential for movement, ensuring your cargo arrives at its destination in the same condition it left.

Types of Load Locks for Pickup Trucks

The market offers a variety of load locking solutions, each with specific strengths. Understanding these types is key to selecting the right tools for your hauling needs.

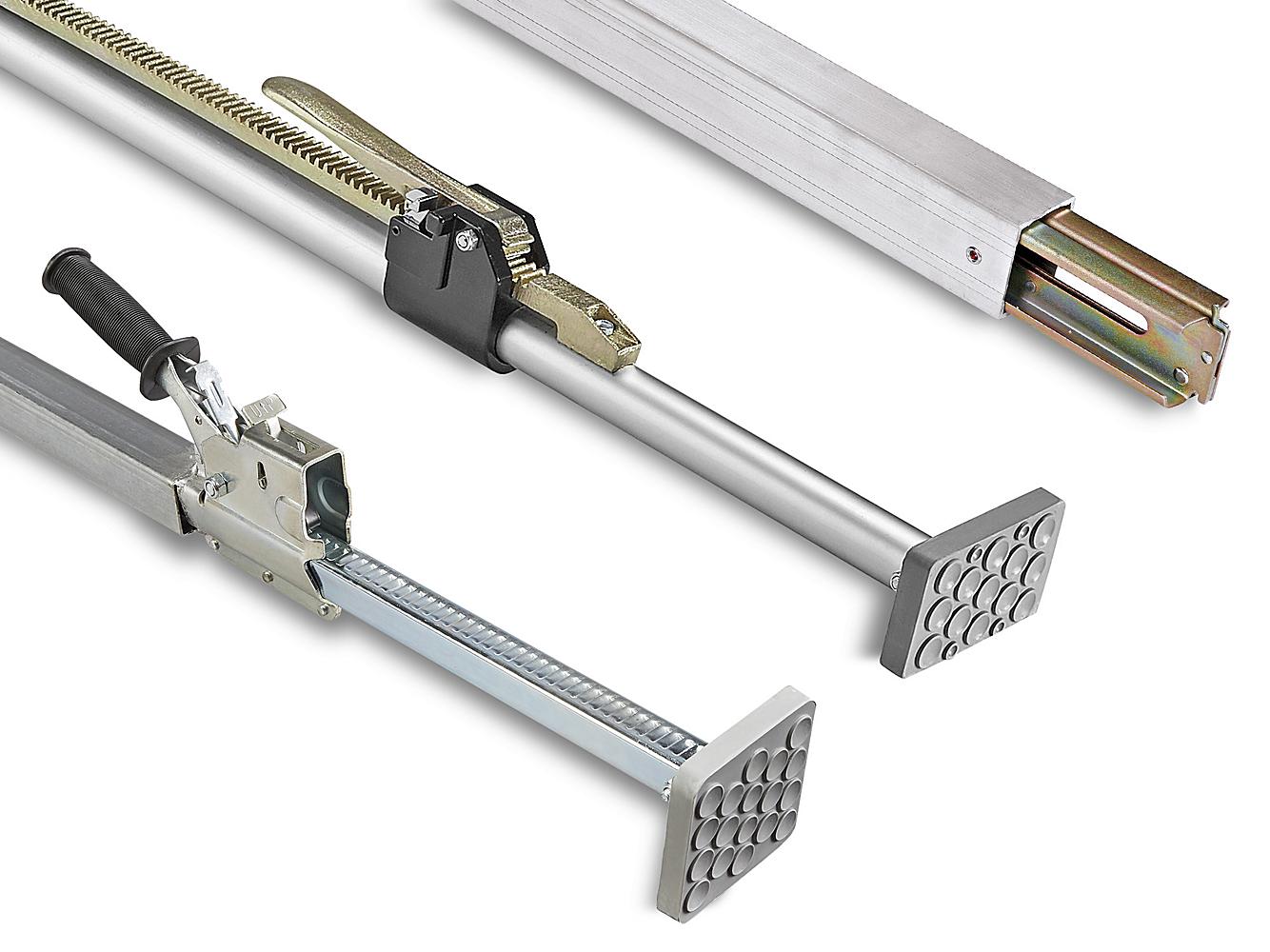

1. Cargo Bars / Load Bars / Cargo Stabilizers

These are perhaps the most popular and versatile load locks.

- Description: Telescoping bars, typically made of steel or aluminum, featuring spring-loaded mechanisms and rubberized feet on each end.

- Mechanism: They extend to fit snugly across the width or length of the truck bed, exerting pressure against the bed walls to create a sturdy barrier.

- Pros: Extremely easy and quick to install and remove. Excellent for compartmentalizing the bed, preventing items from sliding forward or backward. Versatile for various load sizes.

- Cons: Primarily designed for preventing sliding. While they provide strong resistance, they may not be sufficient on their own for extremely heavy or top-heavy items that require downward pressure.

2. Cargo Nets & Bungee Nets

Ideal for securing smaller, lighter, or irregularly shaped items.

- Description: Elasticized nets with multiple attachment points (hooks) that stretch over cargo.

- Mechanism: They conform to the shape of the cargo, providing downward and lateral pressure to prevent movement and bounce.

- Pros: Highly adaptable to various shapes and sizes of cargo. Excellent for containing loose items like groceries, sports equipment, or tools. Quick to deploy.

- Cons: Limited in their ability to secure very heavy or rigid items. Elasticity can degrade over time. Not a primary solution for large, single items.

3. Ratchet Straps & Cam Buckle Straps (Tie-Downs)

While often thought of simply as "tie-downs," these are fundamental load locks.

- Description: Strong webbing straps equipped with either a ratchet mechanism for high tension or a cam buckle for quick, moderate tension.

- Mechanism: They cinch cargo down to the truck’s anchor points (D-rings, cleats) preventing vertical lift and horizontal movement.

- Pros: Offer superior securing power, essential for heavy, bulky, or fragile items. Highly versatile for a wide range of loads.

- Cons: Can be time-consuming to set up. Requires proper technique to avoid overtightening (which can damage cargo or straps) or undertightening. Can wear on cargo edges if not protected.

4. Truck Bed Dividers & Organizers

More permanent or semi-permanent solutions for structured cargo management.

- Description: Systems that create fixed or adjustable partitions within the truck bed, often integrated with bed rail systems.

- Mechanism: Physically separates the bed into compartments, preventing items from mixing or shifting across the entire bed.

- Pros: Excellent for organization and dedicated storage. Provides robust containment for specific types of cargo.

- Cons: Less flexible for rapidly changing cargo needs compared to portable bars. May require specific truck bed rail systems.

5. Wheel Chocks & Straps (for wheeled vehicles)

Specialized load locks for ATVs, motorcycles, lawnmowers, etc.

- Description: Wedges placed against vehicle wheels, often combined with dedicated wheel straps that secure the tires or frame to anchor points.

- Mechanism: Prevents the wheeled vehicle from rolling or shifting forward/backward. Straps provide crucial downward and lateral stability.

- Pros: Essential for safely transporting wheeled vehicles. Prevents damage to vehicle suspension during transit.

- Cons: Specific use case, not for general cargo.

Why Are Load Locks Essential? Benefits Beyond Basic Security

Investing in and properly using load locks offers a multitude of benefits that extend far beyond simply keeping items from falling out of your truck.

- Enhanced Safety: The primary benefit. Unsecured loads are a major cause of road accidents, injuries, and even fatalities. Load locks prevent cargo from becoming dangerous projectiles.

- Cargo Protection: Prevents your valuable items from getting scratched, dented, broken, or otherwise damaged by shifting or colliding with the truck bed or other cargo.

- Vehicle Protection: Safeguards your truck bed, tailgate, and cab from impact damage, scuffs, and dents caused by unsecured loads.

- Legal Compliance: Many states and jurisdictions have strict laws against unsecured loads. Fines can be hefty, and you could be liable for damages or injuries caused by falling cargo.

- Efficiency & Peace of Mind: Knowing your cargo is secure reduces stress during transit. It also allows for quicker loading and unloading as you spend less time repositioning shifted items.

- Fuel Efficiency: While minor, a shifting load can subtly alter your truck’s balance and aerodynamics, potentially impacting fuel economy over long distances. A well-secured load contributes to stable driving.

Choosing the Right Load Lock System: Factors to Consider

Selecting the best load lock solution depends on your specific needs. Ask yourself these questions:

- Type of Cargo: What are you primarily hauling? Small items, large boxes, furniture, vehicles, construction materials? Consider weight, fragility, and shape.

- Frequency of Use: Do you need a quick daily solution, or something for occasional heavy hauls?

- Truck Bed Configuration: Does your truck have a bed liner, tie-down points, bed rails, or a tonneau cover that might interfere with certain systems?

- Budget: Load locks range from inexpensive bungee cords to robust, integrated bed systems. Balance cost with quality and anticipated use.

- Ease of Use vs. Security Level: Some solutions are faster to deploy but offer less ultimate security, while others provide maximum security but require more setup time.

- Material Quality & Durability: Look for corrosion-resistant materials, strong webbing, and robust mechanisms, especially if you’ll be using them frequently or in harsh weather.

Practical Guide: How to Effectively Use Load Locks

Proper technique is just as important as having the right tools.

-

Pre-Load Check:

- Inspect all load locks for wear, fraying, or damage before each use. Never use compromised equipment.

- Plan your cargo layout: Place the heaviest items first, as low as possible, and centered in the bed to maintain vehicle stability.

-

Placement Strategy:

- Cargo Bars: Use bars to create "walls" around your cargo. For example, place one bar behind your load to prevent it from sliding backward, and another in front to prevent forward movement. Multiple bars can create smaller compartments for different items.

- Cargo Nets: Drape nets over loose items or smaller piles of cargo. Secure all hooks to available tie-down points.

- Ratchet Straps: Use at least two straps for any significant load, preferably crossing them for multi-directional security. Attach hooks to strong, designated anchor points in your truck bed. For wheeled vehicles, ensure straps are pulled from opposing angles to prevent movement.

-

Securing Technique:

- Cargo Bars: Extend the bar until it’s firmly pressed against both bed walls. Ensure the rubber feet have a good grip and aren’t on a slippery surface.

- Ratchet Straps: Pull the slack out first, then use the ratchet to apply tension. The strap should be taut, but not so tight that it damages the cargo or the strap itself. A good rule of thumb is "guitar string tight" – you should be able to pluck it and hear a low thrum.

- Edge Protection: Use corner protectors or padding under straps to prevent damage to fragile cargo or to the straps themselves from sharp edges.

-

Post-Load Check:

- Once everything is loaded and seemingly secure, give each item a firm push or pull. It shouldn’t budge.

- After driving a short distance (e.g., the first 5-10 miles), pull over safely and re-check all load locks. Cargo can settle, and straps may loosen slightly. Re-tension if necessary.

-

Maintenance & Storage:

- Clean dirt and debris from straps and bars after use.

- Store load locks in a dry place, away from direct sunlight and extreme temperatures, to prolong their lifespan.

- Periodically inspect for signs of wear, especially on webbing and moving parts.

Common Challenges and Solutions

- Slippery Cargo/Bed: Use anti-slip mats (e.g., rubberized grip mats) under your cargo. Some cargo bars come with enhanced rubber feet for better grip.

- Oddly Shaped Items: This often requires a combination of load locks. Use a cargo bar to block a large item, then use straps to secure it further, and a net for any smaller accompanying items.

- Insufficient Anchor Points: Consider aftermarket tie-down anchors that can be installed in your truck bed or integrated rail systems that offer more flexible attachment points.

- Over-tightening Straps: This can damage your cargo or the straps. Learn the proper tensioning technique. If in doubt, err on the side of slightly less tension and use more straps.

- Cargo Bars Slipping: Ensure your truck bed walls are clean and dry where the bar makes contact. Invest in higher-quality bars with robust, non-slip rubber feet.

Load Locks For Pickup Trucks: Estimated Price Guide

Please note that prices can vary significantly based on brand, material quality, features, and retailer. These are general estimated ranges.

| Item Type | Description | Estimated Price Range (USD) | Key Features / Notes |

|---|---|---|---|

| Cargo Bar | Telescoping steel/aluminum bar with spring-loaded mechanism and rubber feet | $30 – $80 | Adjustable length, easy to install/remove, ideal for compartmentalizing. Higher end for heavy-duty, wider trucks. |

| Cargo Net | Elastic bungee net for truck beds (various sizes) | $20 – $60 | Different mesh sizes, typically includes hooks. Great for containing loose or irregularly shaped items. Larger nets cost more. |

| Ratchet Straps | Set of 4 (1" or 2" wide, 10-20 ft long) with hooks | $25 – $75 | Working Load Limit (WLL) is crucial. Higher WLL, wider straps, and better hardware increase price. Essential for securing heavy loads. |

| Cam Buckle Straps | Set of 4 (1" wide, 10-15 ft long) with hooks | $15 – $40 | Quicker to use than ratchets, but offer less tension. Good for lighter loads or securing items that don’t need extreme pressure. |

| Truck Bed Divider | Basic adjustable divider (non-integrated) | $60 – $150 | Can be fixed or adjustable. More expensive for OEM-specific or integrated rail systems. Offers structured organization. |

| Wheel Chocks | Pair of heavy-duty wheel chocks for vehicles | $25 – $70 | Essential for securing wheeled vehicles (ATVs, motorcycles). Often used in conjunction with specific wheel straps. |

| Anti-Slip Mat | Rubberized mat for truck bed liner | $30 – $80 | Prevents cargo from sliding on the bed floor. Can be cut to size. A must-have for slippery cargo or bed liners. |

| Corner Protectors | Set of 4 plastic or rubber protectors for straps | $10 – $25 | Prevents strap abrasion on sharp edges of cargo and distributes pressure, protecting fragile items. |

Frequently Asked Questions (FAQ)

Q1: Are load locks legally required?

A1: While specific "load lock" devices aren’t always explicitly mandated, nearly all states have laws requiring that loads be "secure" or "prevented from escaping or dropping." Using load locks helps you comply with these general unsecured load laws and avoid fines or liability.

Q2: Can I use just one cargo bar to secure everything?

A2: It depends entirely on the load. For a few light boxes, one bar might suffice. For heavier or multiple items, it’s safer to use multiple bars to create compartments, or combine a bar with ratchet straps for comprehensive security. Never rely on a single point of failure for critical loads.

Q3: How do I prevent cargo bars from slipping on my bed liner?

A3: Ensure both the bed liner surface and the rubber feet of the bar are clean and dry. Some high-quality cargo bars have larger, more aggressive rubber pads for better grip. An anti-slip mat laid under the cargo and the bar’s feet can also significantly improve stability.

Q4: What’s the difference between a bungee cord and a cargo net?

A4: Bungee cords are typically single elastic cords with hooks on each end, used for securing individual, smaller items or providing light tension. A cargo net is a web of bungee cords or elastic webbing, offering much more surface area coverage and multiple attachment points, making it better for containing multiple loose items or irregularly shaped cargo.

Q5: How often should I check my load while driving?

A5: It’s highly recommended to check your load after the first 5-10 miles of driving, as cargo can settle and straps can loosen. For longer trips, pull over every couple of hours or at fuel stops to quickly re-check tension and positioning.

Q6: Can load locks damage my truck bed or cargo?

A6: If misused, yes. Over-tightening ratchet straps can crush fragile cargo or deform the truck bed. Improperly placed cargo bars can scratch bed walls if they slip. However, when used correctly and with appropriate padding/protection, load locks are designed to prevent damage, not cause it.

Conclusion

Load locks are not just accessories; they are fundamental safety equipment for any pickup truck owner. By understanding the different types available, considering your specific hauling needs, and diligently applying proper securing techniques, you can transform your truck bed from a potential hazard into a reliable, secure cargo transport system. Investing in quality load locks and making their proper use a consistent habit will safeguard your cargo, protect your vehicle, and most importantly, ensure the safety of everyone on the road. Drive smart, drive secure, and make load locks an indispensable part of your pickup truck experience.