Lorry Parts Names List: An In-Depth Guide to the Anatomy of a Commercial Vehicle pickup.truckstrend.com

Introduction: The Unsung Heroes of the Road

Lorry parts – often referred to as truck parts or commercial vehicle components – are the intricate building blocks that collectively enable the colossal machines we see traversing our roads daily. Far more complex than typical passenger cars, lorries are engineering marvels designed for heavy-duty work, long hauls, and demanding conditions. Understanding the "Lorry Parts Names List" is not merely an academic exercise; it’s fundamental for anyone involved in the trucking industry – from mechanics and fleet managers to drivers and logistics professionals. A comprehensive knowledge of these components is crucial for effective maintenance, efficient repairs, accurate troubleshooting, and ultimately, ensuring the safety and reliability of these vital vehicles that keep our global economy moving. This article aims to be a detailed guide, breaking down the complex anatomy of a lorry into understandable sections, providing practical insights, and offering a foundational understanding of the multitude of parts that make up these powerful machines.

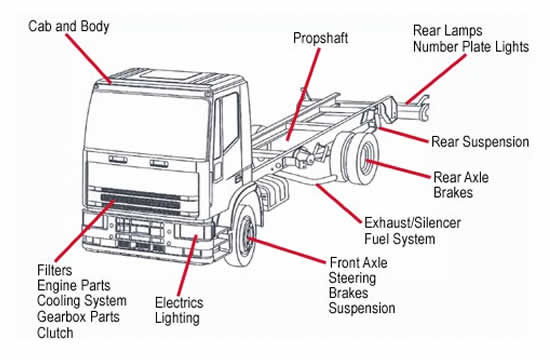

Lorry Parts Names List: An In-Depth Guide to the Anatomy of a Commercial Vehicle

The Heart of the Beast: Engine and Fuel System Components

The engine is the powerhouse of any lorry, converting fuel into mechanical energy to propel the vehicle. Its components are meticulously engineered for durability and efficiency.

- Cylinder Block & Head: The fundamental structure housing the cylinders where combustion occurs. The cylinder head seals the top of the cylinders and contains the valves.

- Pistons & Connecting Rods: Pistons move up and down within the cylinders, converting combustion pressure into mechanical force, which is transferred to the crankshaft via connecting rods.

- Crankshaft: Converts the linear motion of the pistons into rotational motion, which then drives the transmission.

- Camshaft: Controls the opening and closing of the engine’s intake and exhaust valves, ensuring proper timing for combustion.

- Valves (Intake & Exhaust): Regulate the flow of air-fuel mixture into and exhaust gases out of the cylinders.

- Fuel Injectors: Precisely spray fuel into the combustion chambers, atomizing it for efficient burning.

- Fuel Pump: Delivers fuel from the tank to the engine, maintaining adequate pressure.

- Turbocharger/Supercharger: Increases engine power by forcing more air into the cylinders, especially crucial for heavy-duty engines.

- Exhaust Manifold & System: Collects exhaust gases from the cylinders and directs them through the exhaust pipe, often incorporating a Diesel Particulate Filter (DPF) and Selective Catalytic Reduction (SCR) system for emissions control.

- Oil Pump & Sump: Circulates lubricating oil throughout the engine to reduce friction and dissipate heat; the sump stores the oil.

- Radiator & Cooling System Components: Manages engine temperature. Includes the radiator (dissipates heat), water pump (circulates coolant), thermostat (regulates coolant flow), and cooling fan.

- Alternator: Generates electrical power to run the lorry’s electrical systems and recharge the battery.

- Starter Motor: Engages the engine’s flywheel to crank and start the engine.

- Glow Plugs (Diesel) / Spark Plugs (Petrol): Assist in starting the engine, particularly in cold weather for diesel, or ignite the air-fuel mixture in petrol engines.

- Timing Belt/Chain: Synchronizes the crankshaft and camshaft rotation, critical for valve timing.

Putting Power to the Wheels: Transmission and Drivetrain

The transmission system transmits power from the engine to the drive wheels, allowing for varying speeds and torque.

- Clutch Assembly: Disengages and engages the engine from the transmission, allowing for gear changes. Comprises the clutch disc, pressure plate, and release bearing.

- Gearbox (Transmission): Contains a series of gears that allow the driver to select different ratios for varying speeds and torque requirements. Can be manual, automated manual (AMT), or automatic.

- Driveshaft (Propeller Shaft): Transmits rotational power from the gearbox to the differential.

- Universal Joints (U-joints): Flexible joints on the driveshaft that accommodate changes in angle as the suspension moves.

- Differential: Allows the drive wheels to rotate at different speeds when cornering, while still receiving power.

- Axles (Drive Axles): The shafts that transfer power from the differential to the wheels. Lorries often have multiple drive axles for increased traction and load capacity.

The Backbone: Chassis and Frame Components

The chassis forms the structural foundation of the lorry, supporting all other components and bearing the load.

- Frame Rails (Longitudinal Members): The main parallel beams that run the length of the vehicle, forming the core structure.

- Crossmembers: Beams that connect the frame rails, providing rigidity and support for mounted components.

- Mounting Brackets: Secure various components like the engine, transmission, suspension, and body to the frame.

- Fifth Wheel (Tractor Units): A coupling device on tractor units that connects and supports a semi-trailer, allowing it to pivot.

- Kingpin (Trailer): A vertical pin on the front of a semi-trailer that locks into the fifth wheel.

Safety First: Braking System

A lorry’s braking system is paramount for safety, designed to stop massive loads efficiently and reliably.

- Brake Drums/Discs: The rotating components that friction material presses against to create braking force. Drums are common on rear axles, discs on front.

- Brake Pads/Linings: Friction material that presses against the drums or discs to slow the vehicle.

- Calipers (Disc Brakes): House the brake pads and hydraulic/pneumatic pistons that push the pads against the disc.

- Wheel Cylinders (Drum Brakes): Actuated by air/hydraulic pressure to force brake shoes against the drum.

- Master Cylinder (Hydraulic Brakes): Converts pedal pressure into hydraulic pressure to activate the brakes.

- Air Compressor & Air Tanks (Air Brakes): Generates and stores compressed air for the air braking system, common in lorries.

- Brake Chambers: Convert compressed air into mechanical force to apply the brakes.

- Brake Lines & Hoses: Conduits for hydraulic fluid or compressed air.

- Valves (Relay, Protection, Leveling): Regulate air pressure and distribution within the air brake system.

- ABS (Anti-lock Braking System) Sensors & Modulator: Prevent wheel lock-up during braking, enhancing control.

- Slack Adjusters: Automatically or manually adjust the distance between the brake shoes/pads and the drum/disc as they wear.

Smooth Ride & Stability: Suspension System

The suspension system absorbs road shocks, maintains tire contact with the road, and provides stability.

- Leaf Springs: Layers of steel leaves that flex to absorb shocks, common on heavy-duty lorries.

- Coil Springs: Helical springs that compress to absorb shocks, less common than leaf springs in heavy lorries but found in some applications.

- Shock Absorbers (Dampers): Control the oscillations of springs, preventing excessive bouncing.

- Air Bags (Air Suspension): Inflatable rubber bags that replace or supplement traditional springs, offering adjustable ride height and superior ride comfort.

- Anti-Roll Bars (Stabilizer Bars): Reduce body roll during cornering, improving stability.

- Control Arms/Radius Rods: Connect the axle to the chassis, controlling wheel movement.

- Bushings: Rubber or polyurethane components that cushion joints and reduce vibration.

Direction and Control: Steering System

The steering system allows the driver to control the direction of the lorry.

- Steering Wheel: The driver’s primary interface for steering input.

- Steering Column: Connects the steering wheel to the steering box/rack.

- Steering Box (Gearbox) / Rack and Pinion: Converts rotational input from the steering column into linear motion to turn the wheels. Steering boxes are common in lorries.

- Power Steering Pump: Provides hydraulic pressure to assist the driver in turning the wheels.

- Drag Link & Tie Rods: Linkage components that transmit steering motion from the steering box to the steering knuckles and wheels.

- Kingpins: Pivots around which the steering knuckles (and thus the wheels) turn.

The Nervous System: Electrical and Lighting Components

The electrical system powers everything from engine starting to cabin comforts and critical safety lights.

- Battery: Stores electrical energy for starting and powering accessories when the engine is off.

- Wiring Harness: Bundles of wires that distribute electrical power and signals throughout the lorry.

- Fuses & Relays: Protect electrical circuits from overloads and control high-current components.

- Headlights, Tail Lights, Indicator Lights: Essential for visibility and signaling, adhering to strict regulations.

- Wipers & Washer System: Maintain clear visibility through the windshield.

- Horn: A crucial safety device for alerting others.

- Dashboard Gauges & Displays: Provide vital information to the driver (speed, RPM, fuel level, pressure, temperature).

- ECU (Engine Control Unit) / ECM (Electronic Control Module): The "brain" of the engine, managing fuel injection, ignition, and emissions.

- Sensors (Temperature, Pressure, Speed, ABS, etc.): Provide data to the ECU and other control systems.

Driver’s Command Center: Cabin and Interior Components

The cabin is the driver’s workspace and living area for long-haul operations.

- Seats: Ergonomically designed, often air-suspended, for driver comfort during long hours.

- Dashboard: Houses gauges, controls, and infotainment systems.

- Pedals (Accelerator, Brake, Clutch): Driver input controls.

- Steering Wheel: As above, part of the interior interface.

- Mirrors (Side, Rear-view): Essential for visibility and safety.

- Windows & Door Mechanisms: Provide access and ventilation.

- HVAC (Heating, Ventilation, Air Conditioning) System: Maintains cabin climate.

- Sleepers: Integrated sleeping berths in long-haul lorries.

The Outer Shell: Body and Exterior Components

These parts define the lorry’s appearance and contribute to its aerodynamics and protection.

- Cab: The enclosed compartment for the driver and passengers.

- Hood (Bonnet): Covers the engine compartment.

- Fenders (Mudguards): Protect the body from road spray and debris.

- Doors: Provide entry and exit to the cab.

- Bumpers: Absorb minor impacts and protect the front/rear of the vehicle.

- Grille: Allows airflow to the radiator and engine.

- Aerodynamic Fairings: Reduce air resistance, improving fuel efficiency.

- Mud Flaps: Prevent debris from being thrown by the wheels.

Practical Advice and Actionable Insights for Lorry Parts Management

Understanding lorry parts is just the first step; practical application is key.

- Know Your Vehicle: Keep a detailed record of your lorry’s make, model, year, and VIN (Vehicle Identification Number). This information is crucial for ordering the correct parts.

- Regular Inspections: Implement a routine inspection schedule. Early detection of wear or damage can prevent costly breakdowns and extend part life.

- Quality Over Price: While budget is a factor, prioritizing genuine OEM (Original Equipment Manufacturer) or high-quality aftermarket parts is vital for safety, performance, and longevity. Cheap parts often lead to repeat repairs.

- Understand Compatibility: Not all parts are universal. Ensure the part is compatible with your specific lorry’s specifications, including engine type, axle configurations, and transmission.

- Preventative Maintenance: Follow manufacturer-recommended maintenance schedules for fluid changes, filter replacements, and component inspections. This proactive approach significantly reduces the likelihood of part failure.

- Seek Expert Advice: Don’t hesitate to consult with experienced mechanics or parts suppliers. Their expertise can save you time and money.

- Keep a Basic Spares Kit: For long hauls, consider carrying essential spares like fuses, belts, hoses, and basic tools.

Concluding Summary: The Synergy of Components

The "Lorry Parts Names List" is a testament to the incredible complexity and robust engineering behind commercial vehicles. From the roaring power of the engine to the intricate network of the electrical system, each component plays a critical, interdependent role in the lorry’s overall function. A thorough understanding of these parts empowers individuals in the trucking industry to make informed decisions regarding maintenance, repair, and operational efficiency. By prioritizing quality, adhering to maintenance schedules, and continuously expanding one’s knowledge, we ensure that these vital machines remain safe, reliable, and capable of delivering the goods that drive our world. The lorry, in its entirety, is a magnificent symphony of parts working in perfect harmony.

Sample Lorry Parts Price Table (Illustrative Prices)

Disclaimer: Prices are approximate and highly variable based on brand (OEM vs. Aftermarket), quality, region, supplier, and specific lorry model. This table serves as an example and should not be used for actual purchasing decisions.

| Part Name | System | Description/Function | Estimated Price Range (USD) |

|---|---|---|---|

| Fuel Injector | Engine & Fuel System | Delivers precise fuel spray into combustion chamber | $150 – $600 (each) |

| Radiator | Engine & Fuel System | Dissipates heat from engine coolant | $400 – $1,500 |

| Alternator | Electrical System | Generates electrical power | $250 – $800 |

| Clutch Kit | Transmission | Engages/disengages engine from transmission | $500 – $2,000 |

| Brake Pads (Set for Axle) | Braking System | Friction material for disc brakes | $100 – $400 |

| Air Bag (Suspension) | Suspension System | Inflatable rubber component for air suspension | $200 – $700 |

| Shock Absorber | Suspension System | Dampens spring oscillations | $50 – $200 (each) |

| Steering Box | Steering System | Converts steering input to wheel turning | $700 – $2,500 (new/reman) |

| Headlight Assembly | Electrical System | Provides forward illumination | $150 – $600 (each) |

| DPF (Diesel Particulate Filter) | Exhaust System | Filters soot from diesel exhaust gases | $1,000 – $5,000+ |

| Water Pump | Engine & Fuel System | Circulates coolant through the engine | $100 – $400 |

| Air Compressor (Brakes) | Braking System | Generates compressed air for braking | $400 – $1,200 |

| Leaf Spring (Single) | Suspension System | Provides basic suspension and load support | $150 – $600 |

| Driveshaft (Standard) | Drivetrain | Transmits power from transmission to differential | $300 – $1,000 |

| Air Filter Element | Engine & Fuel System | Filters air entering the engine | $30 – $100 |

Frequently Asked Questions (FAQ) about Lorry Parts

Q1: What’s the difference between OEM and aftermarket lorry parts?

A1: OEM (Original Equipment Manufacturer) parts are made by the same company that manufactured your lorry’s original components. Aftermarket parts are produced by other companies. OEM parts generally offer guaranteed fit and quality but can be more expensive. Aftermarket parts offer more variety in price and performance, but quality can vary widely.

Q2: How often should I replace common wear-and-tear parts like brake pads or filters?

A2: The replacement interval varies significantly based on the part, driving conditions, load carried, and manufacturer recommendations. Always consult your lorry’s owner’s manual or a qualified mechanic for specific maintenance schedules. Regular inspections are key to identifying wear before it becomes critical.

Q3: Can I install lorry parts myself?

A3: While some minor maintenance tasks like changing filters or checking fluids can be done by a knowledgeable individual, most lorry parts require specialized tools, technical expertise, and safety precautions. For critical systems like brakes, engine, or transmission, it’s highly recommended to use a certified lorry mechanic to ensure safety and proper function.

Q4: How do I find the correct part for my specific lorry?

A4: The most reliable way is to use your lorry’s VIN (Vehicle Identification Number). This unique code contains all the necessary information about your vehicle’s specifications. Provide the VIN to your parts supplier, along with the make, model, and year of your lorry, to ensure you get the exact compatible part.

Q5: What are some signs that a lorry part is failing?

A5: Common signs include unusual noises (grinding, squealing, clunking), vibrations, fluid leaks, warning lights on the dashboard, reduced performance (loss of power, poor braking), unusual smells, or visible wear/damage. Any of these signs warrant immediate investigation by a professional.