The Blueprint of Culinary Dreams: Mastering the 3D Food Truck Maker pickup.truckstrend.com

The aroma of sizzling street food, the vibrant branding, the hum of generators – the food truck scene is a dynamic and thriving culinary landscape. But before a single burger is flipped or taco assembled, there’s a crucial, often complex, stage: design and planning. This is where the concept of the 3D Food Truck Maker emerges as an indispensable tool, transforming abstract ideas into tangible, visual blueprints. Far more than just a piece of software, a 3D Food Truck Maker represents a comprehensive approach to designing, visualizing, and optimizing every inch of a mobile kitchen, empowering entrepreneurs to build their dream on wheels with unprecedented precision and confidence.

In an industry where space is at a premium and efficiency is key, the ability to virtually construct and iterate on a food truck’s layout before any physical work begins is revolutionary. It mitigates costly errors, accelerates the build process, and ensures that the final product is not just aesthetically pleasing but also highly functional and compliant. This article will delve deep into the world of 3D Food Truck Makers, exploring its multifaceted benefits, guiding you through its application, and addressing crucial considerations for anyone looking to roll out their culinary vision.

The Blueprint of Culinary Dreams: Mastering the 3D Food Truck Maker

What is a 3D Food Truck Maker? Delving into the Concept

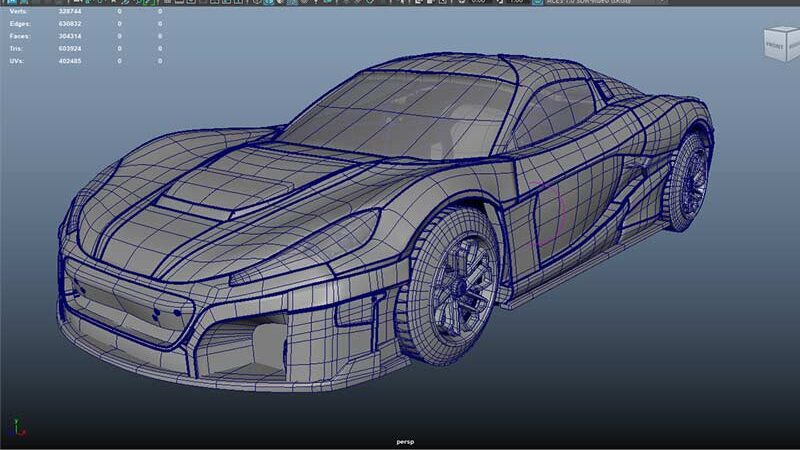

At its core, a "3D Food Truck Maker" refers to the application of three-dimensional modeling and design software to create a virtual representation of a food truck. It’s not a single, proprietary software named "Food Truck Maker," but rather a methodology utilizing various CAD (Computer-Aided Design), BIM (Building Information Modeling), and specialized 3D visualization tools.

These powerful digital environments allow users to:

- Construct a virtual shell: Starting with the exact dimensions of a truck chassis or trailer.

- Populate the interior: Precisely placing kitchen equipment (grills, fryers, refrigerators, sinks, ovens), prep stations, storage units, and service counters.

- Design the exterior: Incorporating windows, serving hatches, entry doors, branding elements, lighting, and custom wraps.

- Simulate utilities: Mapping out plumbing lines, electrical conduits, propane tanks, and ventilation systems.

- Visualize workflow: Understanding how staff will move within the limited space, identifying potential bottlenecks, and optimizing operational flow.

By creating a detailed 3D model, designers and entrepreneurs can experiment with different layouts, materials, and configurations in a risk-free digital space. This virtual prototyping is invaluable for decision-making, allowing for comprehensive planning that was once only possible through expensive and time-consuming physical mock-ups.

The Unparalleled Benefits of Utilizing 3D Food Truck Makers

The adoption of 3D design in food truck construction offers a multitude of advantages that impact every stage of the entrepreneurial journey, from conceptualization to operation.

-

Enhanced Visualization and Communication:

- See Before You Build: The most immediate benefit is the ability to walk through your truck virtually. This eliminates guesswork and ensures that the final product matches your vision perfectly.

- Clearer Communication: High-quality 3D renderings and walkthroughs serve as universal language. They facilitate seamless communication with builders, equipment suppliers, investors, and regulatory bodies, minimizing misunderstandings and misinterpretations. Investors can clearly see the potential, and builders receive precise instructions.

-

Unmatched Customization and Flexibility:

- Infinite Iterations: Experiment with countless layouts, equipment placements, color schemes, and branding elements without incurring any physical costs or delays. Want to try the fryer on the left or the right? See it instantly.

- Optimized Space Utilization: Food trucks are inherently space-constrained. 3D modeling allows for meticulous planning to maximize every square inch, ensuring efficient use of space for equipment, storage, and movement.

-

Significant Cost and Time Efficiency:

- Error Detection: Identify design flaws, clearance issues, and equipment conflicts in the digital realm before construction begins. Catching a mistake in a 3D model is exponentially cheaper and faster than rectifying it during physical build-out.

- Reduced Rework: Fewer on-site changes mean less wasted material, labor, and precious time, leading to faster completion times and lower overall project costs.

- Accurate Quotes: Builders can provide more precise quotes based on detailed 3D plans, leading to fewer budget surprises.

-

Regulatory Compliance and Safety:

- Health Code Planning: Design with local health department regulations in mind from day one. Ensure proper spacing for sanitation, adequate ventilation, and required sink configurations.

- Safety Clearances: Verify that all equipment meets safety standards for clearances from walls, ceilings, and other appliances, preventing fire hazards and ensuring operational safety.

- Accessibility: Plan for ergonomic flow and, if applicable, ADA compliance for customer-facing areas.

-

Operational Flow Optimization:

- Simulate Workflow: Understand the movement patterns of your staff during peak hours. Identify potential bottlenecks in food prep, cooking, serving, and cleaning processes.

- Improve Efficiency: A well-designed layout, informed by 3D simulation, can significantly reduce prep times, minimize unnecessary steps, and improve overall operational efficiency, directly impacting profitability.

-

Powerful Marketing and Fundraising Tool:

- Professional Pitches: Use photorealistic renderings and virtual tours in business plans, investor pitches, and crowdfunding campaigns. A visually compelling design can make a strong impression and secure funding.

- Pre-Launch Hype: Generate excitement and pre-orders by showcasing your future truck’s design on social media, giving potential customers a sneak peek of the experience to come.

How to Use a 3D Food Truck Maker: A Step-by-Step Guide

Embarking on your 3D food truck design journey can seem daunting, but by breaking it down into manageable steps, it becomes an accessible and rewarding process.

-

Step 1: Define Your Culinary Vision & Requirements:

- Menu & Concept: What kind of food will you serve? This dictates the type and quantity of equipment needed.

- Target Audience: Will your truck be for quick grab-and-go, or will it require more elaborate prep?

- Operational Style: How many staff members will be working simultaneously? What’s your desired speed of service?

- Budget: This will influence equipment choices and the complexity of your design.

-

Step 2: Choose Your Software:

- Beginner-Friendly (Free/Low Cost): SketchUp Free (web-based) and Blender (open-source) are excellent starting points. SketchUp is intuitive for basic modeling, while Blender offers immense power with a steeper learning curve.

- Mid-Range (Subscription): SketchUp Pro offers more features and desktop functionality. Fusion 360 (Autodesk) is great for mechanical design and has a strong community.

- Professional (High Cost/Industry Standard): AutoCAD and Revit (Autodesk) are powerful, precise tools often used by architects and engineers, offering extensive features for complex designs and BIM integration.

- Tip: Start with a free option to get comfortable with 3D modeling before investing in professional software.

-

Step 3: Establish the Foundation – The Truck Shell:

- Begin by accurately modeling the dimensions of your chosen truck chassis or trailer. This is your canvas. Pay attention to height, width, length, wheel wells, and any existing structural elements.

- Many software platforms have libraries of basic shapes or even pre-made vehicle models you can adapt.

-

Step 4: Design the Exterior – Branding & Functionality:

- Serving Hatch: Determine its size, placement, and how it opens.

- Windows & Doors: Consider natural light, ventilation, and access points.

- Branding: Apply your logo, color scheme, and graphic wrap to visualize the truck’s overall aesthetic appeal.

- Lighting: Plan for exterior lighting for night operations.

-

Step 5: Layout the Interior – The Kitchen Heart:

- Equipment Placement: This is critical. Start with major appliances (fryers, griddles, ovens, refrigerators, freezers, sinks) and ensure proper clearances.

- Workflows: Arrange equipment logically to support your cooking process (e.g., prep area next to cooking, then serving).

- Sinks: Plan for the required number of sinks (handwashing, three-compartment, prep) and their sizes according to health codes.

- Storage: Design shelving, cabinets, and dry storage areas.

- Tip: Use real-world dimensions for equipment. Many manufacturers provide 3D models or detailed specifications you can import or model yourself.

-

Step 6: Integrate Utilities – The Lifeblood of Your Truck:

- Plumbing: Map out fresh water and greywater tanks, water heater, and pump locations.

- Electrical: Plan for outlets, lighting, and main breaker panel. Consider power requirements for all equipment and generator/shore power connection points.

- Ventilation: Design your exhaust hood system, ensuring it meets health codes for capturing grease and fumes.

- Propane: If using propane, plan for secure tank storage and line routing.

-

Step 7: Refine, Iterate, and Solicit Feedback:

- Review your design from every angle. Use virtual walk-throughs.

- Imagine yourself working in the truck. Does the flow make sense? Are there any cramped areas?

- Share your 3D model or renderings with trusted advisors, experienced food truck owners, or even potential employees for valuable feedback. Make adjustments as needed.

-

Step 8: Render and Export:

- Create high-quality, photorealistic renderings of your interior and exterior.

- Generate floor plans, elevation views, and detailed dimensions for your builder.

- Some software allows for animated walk-throughs, perfect for presentations.

Key Considerations and Best Practices

While 3D modeling offers immense freedom, integrating practical considerations from the outset is vital for a successful outcome.

- Accuracy is Paramount: Measure everything precisely. Even small discrepancies in the 3D model can lead to significant problems during physical construction. Use manufacturer specifications for equipment.

- Ergonomics and Workflow: Design for comfort and efficiency. Staff will spend long hours in the truck, so ensure comfortable working heights, adequate aisle space, and logical flow to minimize fatigue and maximize productivity.

- Ventilation and Fire Suppression: These are non-negotiable for safety and health code compliance. Integrate a robust exhaust hood system and plan for a fire suppression system in your design.

- Weight Distribution: A critical safety factor. Distribute heavy equipment evenly to maintain vehicle balance and prevent tire wear or handling issues. Consult with vehicle experts if unsure.

- Power Requirements: Calculate the total amperage and wattage needed for all appliances. This dictates generator size, electrical panel configuration, and shore power needs. Overlooking this can lead to costly electrical overhauls.

- Material Selection: While 3D models simulate materials, consider their real-world implications: durability, hygiene (stainless steel is standard), weight, and ease of cleaning.

- Future Expansion/Adaptability: If you foresee menu changes or equipment upgrades down the line, design with a degree of flexibility to accommodate future needs.

Types of 3D Food Truck Maker Tools

As mentioned, there isn’t one single "3D Food Truck Maker" software. Instead, various 3D design tools can be leveraged:

-

General-Purpose 3D CAD Software:

- SketchUp: User-friendly, intuitive, great for conceptual design and quick mock-ups. Available in free (web) and paid (Pro) versions.

- Blender: Free, open-source, extremely powerful for modeling, rendering, and animation. Has a steeper learning curve but offers professional-grade results.

- Fusion 360 (Autodesk): Cloud-based, strong for mechanical design, product design, and manufacturing. Offers robust modeling capabilities and simulation tools.

- AutoCAD (Autodesk): Industry standard for 2D drafting and 3D modeling. Highly precise, often used for detailed construction drawings.

-

BIM (Building Information Modeling) Software:

- Revit (Autodesk): Primarily used for architectural design, but its object-oriented approach can be adapted for complex mobile structures, allowing for detailed systems integration (HVAC, plumbing, electrical). More powerful for large-scale projects.

-

Online Configurators/Templates:

- Some food truck manufacturers or custom builders offer basic online configurators that allow you to drag-and-drop pre-designed equipment into a template. While less flexible, they offer a quick visual for general layouts.

-

Specialized Design Services:

- For those not wanting to dive into 3D software, professional designers specializing in food truck layouts can be hired. They use these advanced tools to create custom designs based on your specifications.

Potential Challenges and Solutions

While immensely beneficial, working with 3D design tools can present a few hurdles:

-

Steep Learning Curve:

- Challenge: Professional 3D software can be complex and time-consuming to master.

- Solution: Start with beginner-friendly software like SketchUp. Utilize online tutorials (YouTube is a treasure trove), community forums, and official documentation. Consider short online courses for specific software. If time is critical, hiring a professional 3D designer is a viable option.

-

Software Cost:

- Challenge: Professional CAD/BIM software subscriptions can be expensive.

- Solution: Begin with free alternatives (SketchUp Free, Blender). Factor software subscriptions into your overall business plan if professional tools are deemed necessary. Many offer monthly payment options.

-

Lack of Specific Food Truck Libraries:

- Challenge: Generic 3D software might not have a pre-built library of commercial kitchen equipment specific to food trucks.

- Solution: Many equipment manufacturers provide 3D models (CAD files) of their products for download. Alternatively, learn to model basic shapes and modify existing models to match your equipment dimensions. Online 3D model repositories (e.g., 3D Warehouse for SketchUp) can also be helpful.

-

Overlooking Regulatory Nuances:

- Challenge: Even a perfect 3D model can be non-compliant with local health and safety regulations if not designed correctly.

- Solution: Consult with your local health department and fire marshal early in the design process. Get their requirements in writing and integrate them into your 3D model from the outset. Their input is invaluable.

-

Translating 3D to Reality:

- Challenge: The digital model needs to be accurately translated into a physical build.

- Solution: Work with reputable food truck builders who are experienced in interpreting 3D designs and blueprints. Provide them with detailed dimensions, equipment specifications, and utility plans generated from your 3D model. Regular communication with your builder is key.

Price Table: Investment in 3D Food Truck Design

The cost associated with utilizing a "3D Food Truck Maker" varies significantly depending on the approach you take – whether you design it yourself using software or hire a professional.

| Category | Examples / Description | Estimated Price Range | Key Features & Notes Food Truck Maker is an invaluable tool for entrepreneurs considering building a food truck. It is not just about the technical design; it’s about meticulously planning every detail to ensure operational efficiency, regulatory compliance, and a strong brand presence. By leveraging 3D modeling,